Retrofit & Control System Modernization

Future for your winding machines – powerful, energy-efficient, and sustainable.

Rethinking Control Technology

We modernize your winding machine from the ground up: control systems, electronics, software, fluidics – tailored to your production.

- Complete renewal of the control system

- Control cabinet construction & electronics

- New, intuitive user interface

- Safety functions (Safety Integrated)

- Integration of your existing programs

Your Benefits at a Glance

- Long-term availability of spare parts

- Continued use of your tools

- Higher energy efficiency

- Improved product quality

- Increased production performance

- Reduced downtimes

- Simple & intuitive operation

- Ready for Industry 4.0

- Future-proof investment

Retrofit with Vision

We analyze your machine for potential savings – economically and ecologically.

- Energy efficiency analysis

- Use of energy-efficient drive technology

- Transparent cost-benefit ratio

Project Example: Control System Retrofit

FAG / BR / Meteor /

IWT Industrielle Wickeltechnik GmbH (former manufacturer, insolvent since 2019)

- Control system converted to RAWITEC system

- 1 feed axis + 1 winding spindle with safety

- Adoption of existing winding programs

- Operation without training effort

Or call us directly: +49 911 801 31 01

Retrofit Example: FW322, Year 2006 – formerly IWT Industrial Winding Technology GmbH

- Replacement of older AC drives with modern AC servo motors and controllers

- Complete renewal of machine electronics with state-of-the-art control technology

- Seamless integration of existing winding programs

- Small screen replaced by 15" touchscreen for improved usability

- New joystick for manual and precise axis control

- Safety relays for safe and compliant machine operation

- Existing winding tools can still be used

- Old software replaced by modern, intuitive user interface

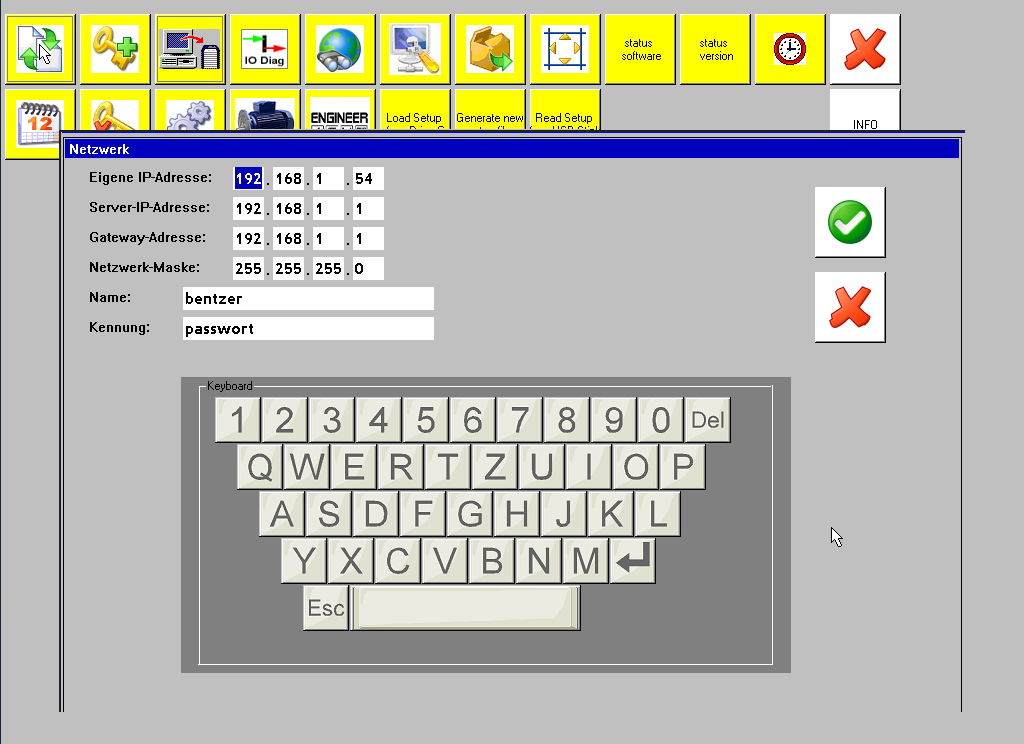

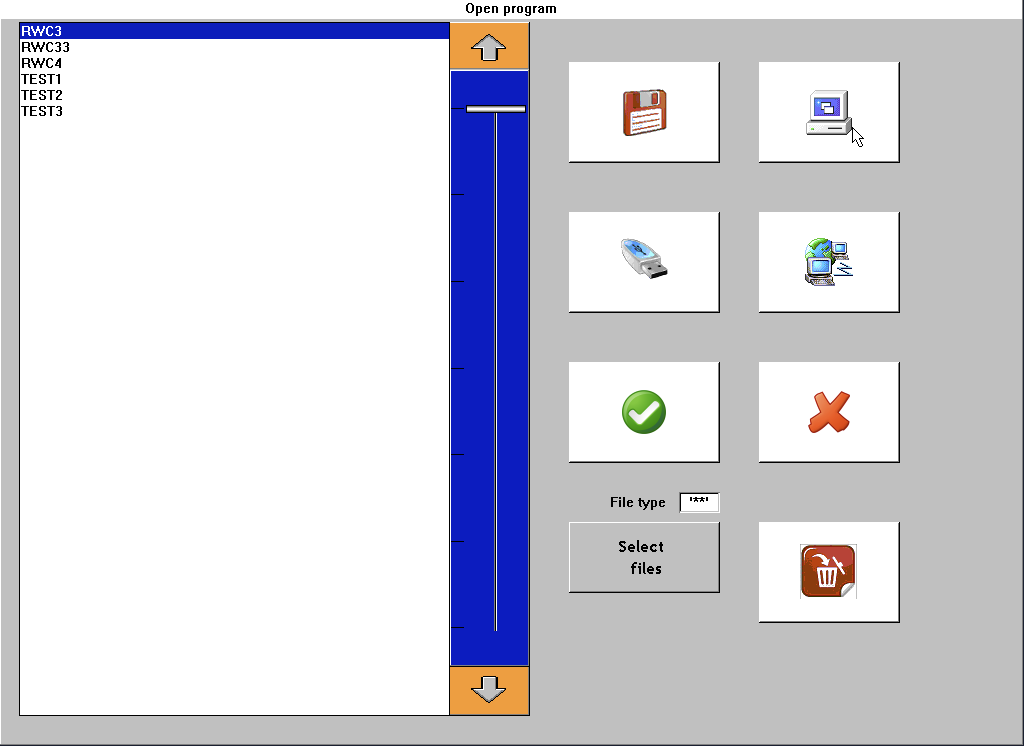

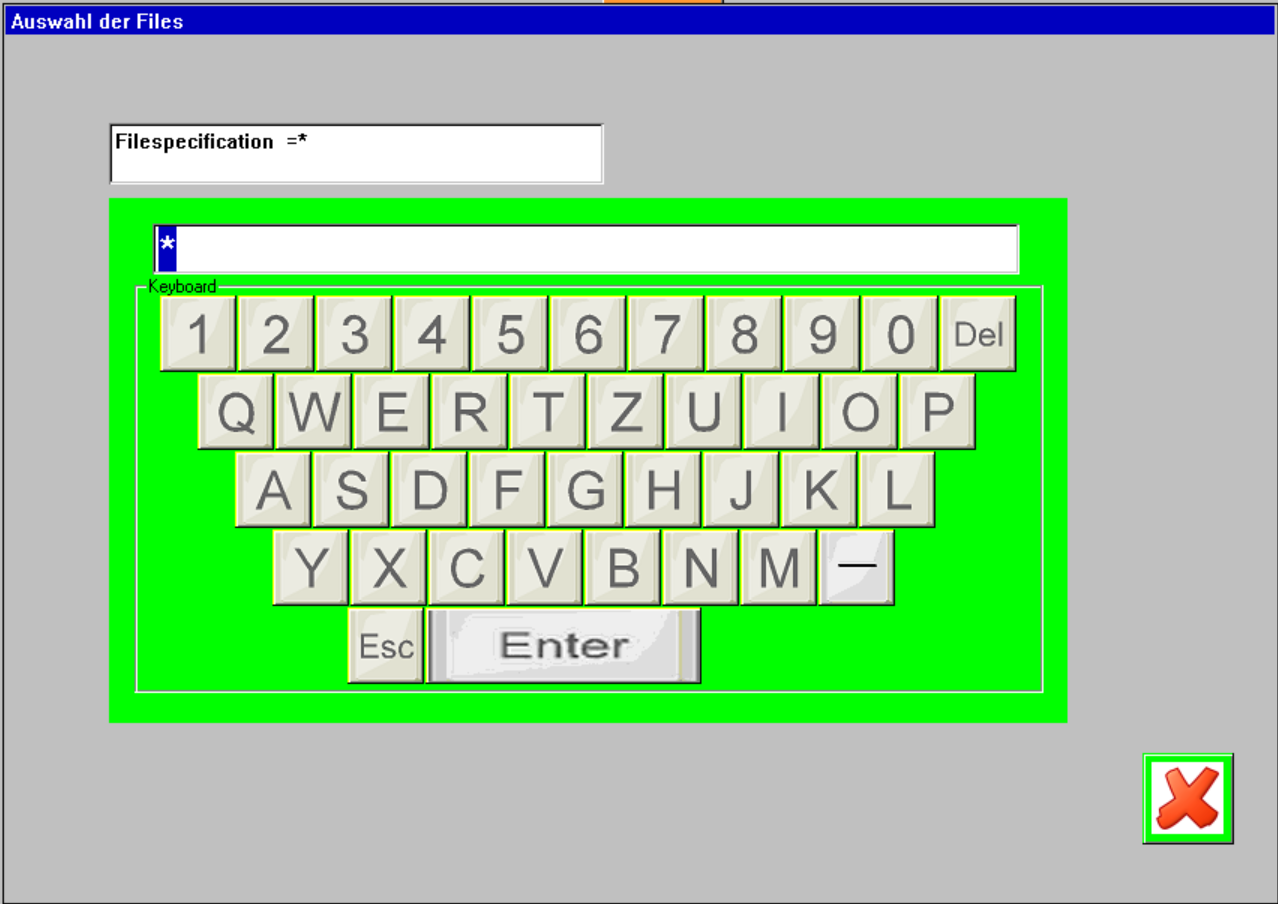

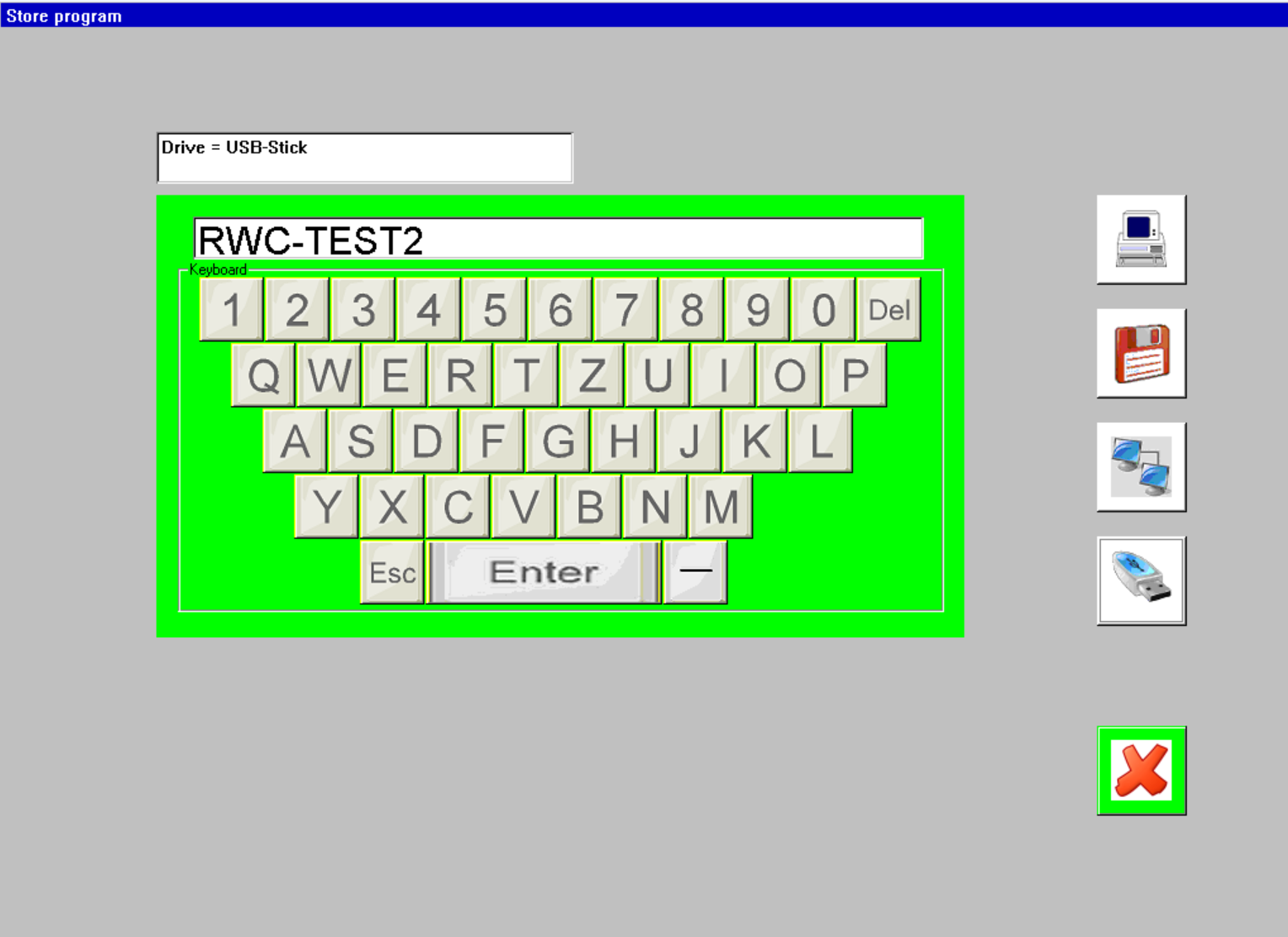

- Program storage via USB, internal PC or network

- Extended functions – saves time and reduces operating costs

Before FW322 / Year 2006

Before FW322 / Year 2006

|

After – RWC322R Modernized / Retrofit Year 2022

After – RWC322R Modernized / Retrofit Year 2022

After – RWC322R Modernized / Retrofit Year 2019/2022

After – RWC322R Modernized / Retrofit Year 2019/2022

|

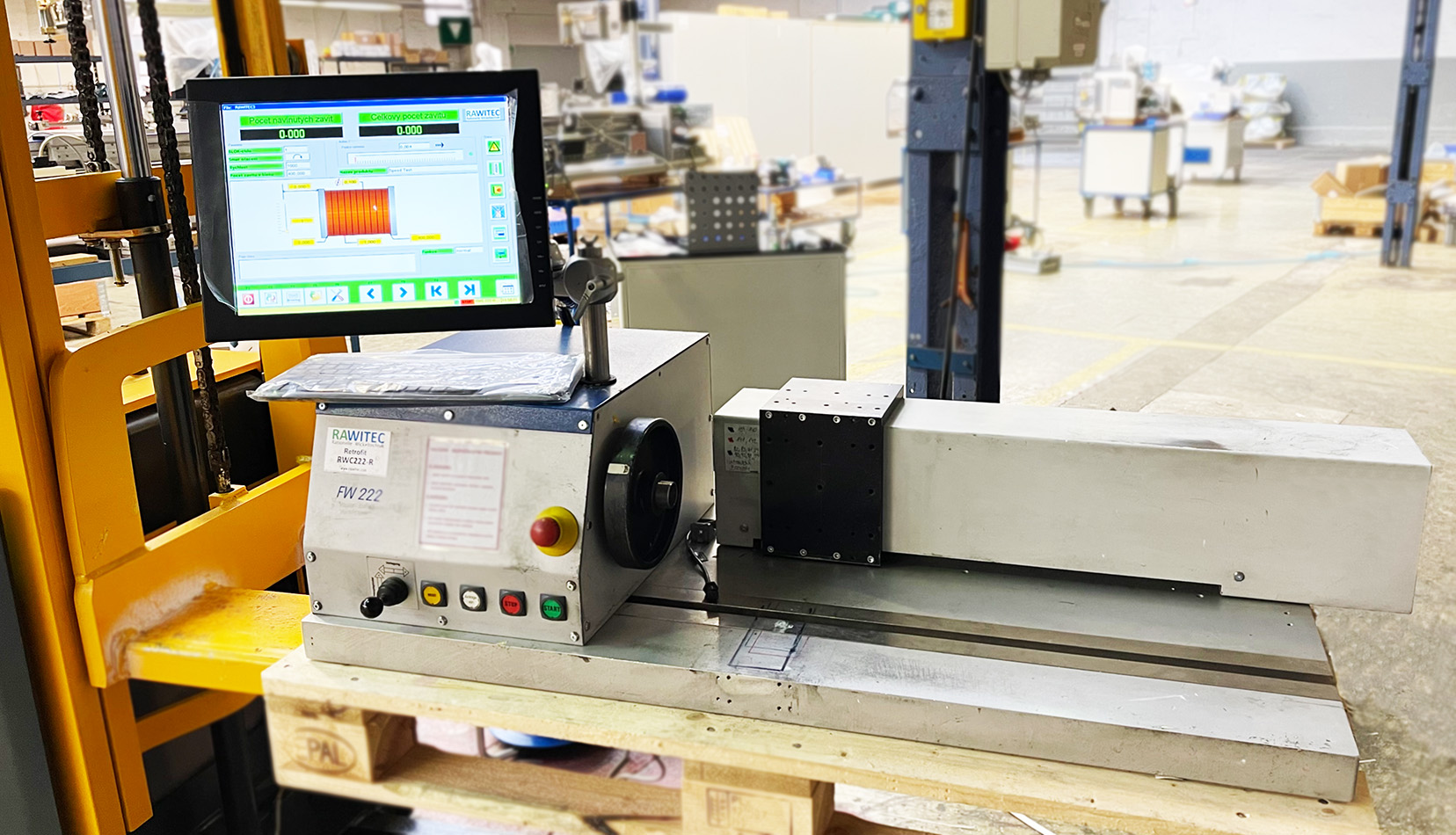

Retrofit Example: FW222, Year 2007 – formerly IWT Industrielle Wickeltechnik GmbH

- Replacement of older AC drives with modern AC servo motors and controllers

- Complete renewal of machine electronics with state-of-the-art control technology

- Seamless integration of existing winding programs

- Small screen replaced by 15" touchscreen for improved usability

- New joystick for manual and precise axis control

- Safety relays for safe and compliant machine operation

- Existing winding tools can still be used

- Old software replaced by modern, intuitive user interface

- Program storage via USB, internal PC or network

- Extended functions – saves time and reduces operating costs

Before FW222 / Year 2007

Before FW222 / Year 2007

|

After – RWC222R Modernized / Retrofit Year 2024

After – RWC222R Modernized / Retrofit Year 2024

|

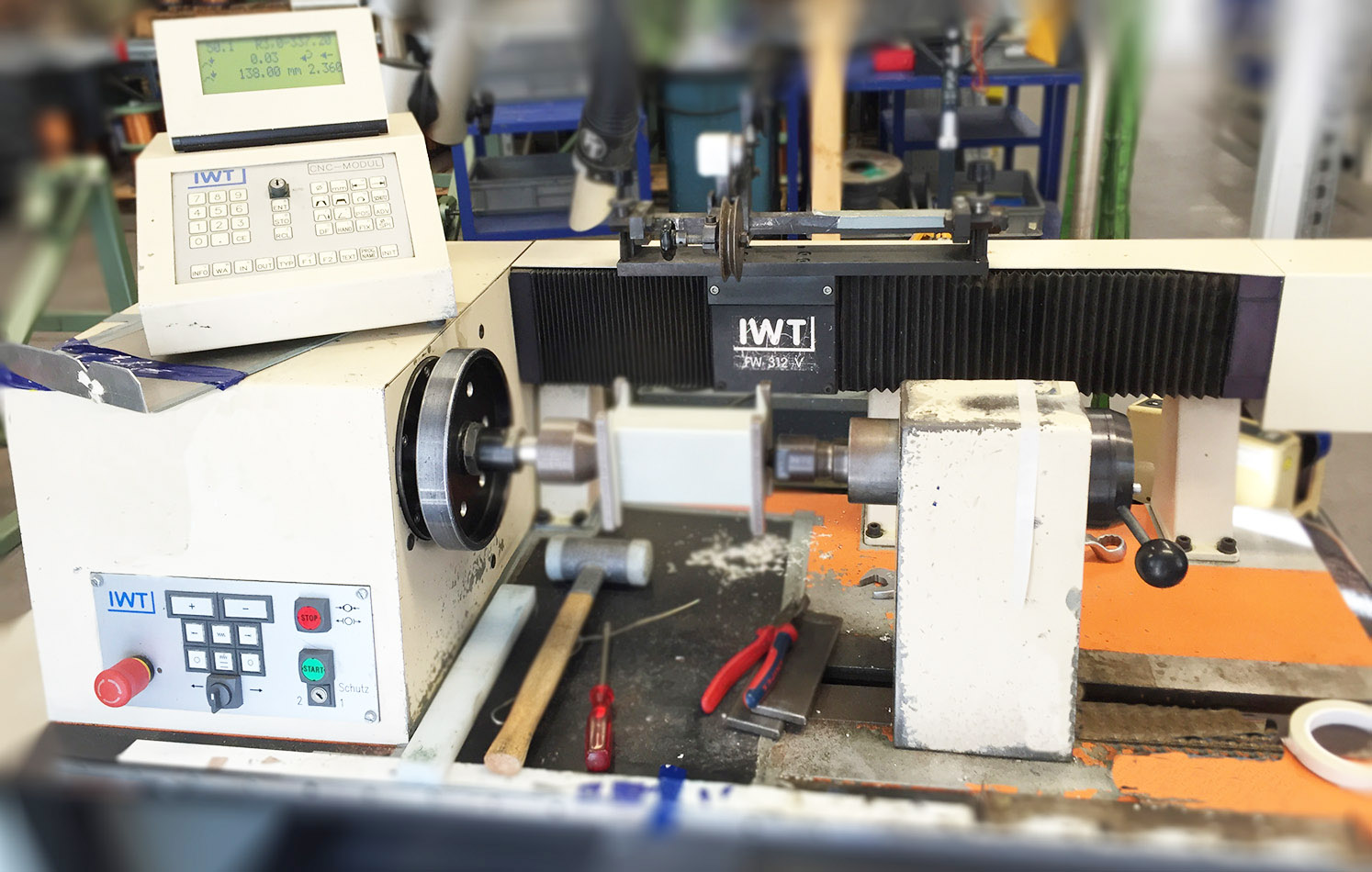

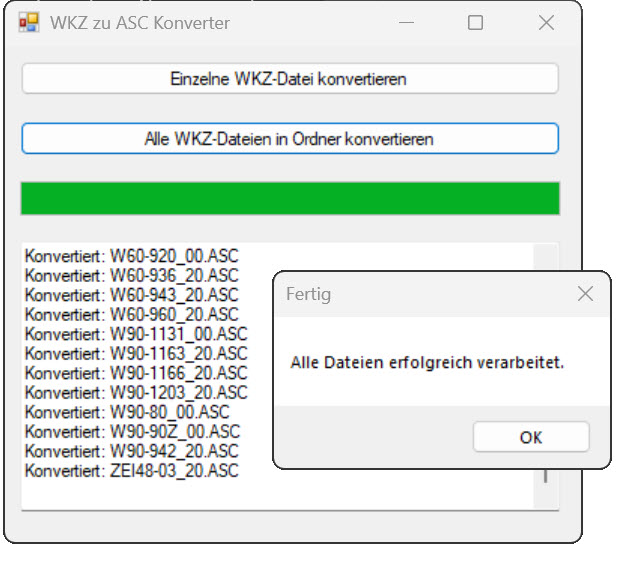

Retrofit Example: FW312V, Year 2001 – formerly IWT Industrielle Wickeltechnik GmbH

- DC drives replaced with modern AC servo motors

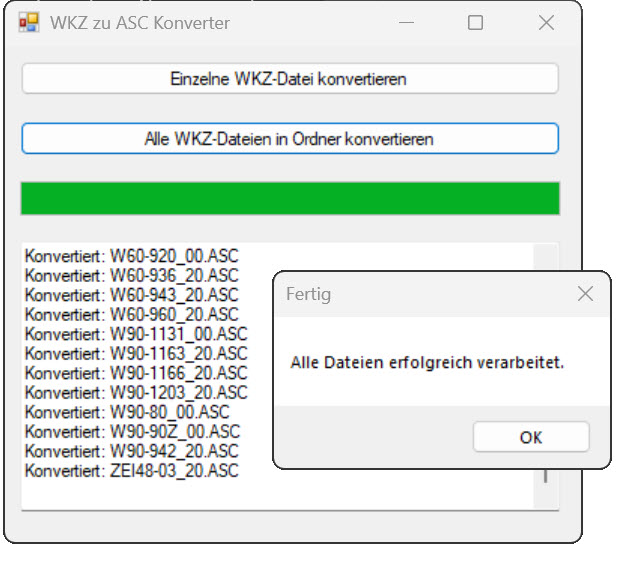

- Existing winding programs converted from database to new PC format

- .wkz winding programs successfully transferred to modern control platform

- New joystick for manual axis control

- Continued use of existing tools

- All known winding parameters remain intact

- New additional functions and options

- Program storage via USB or network

- Time and cost savings for the customer

Before FW312V / Year 1999/2001

Before FW312V / Year 1999/2001

|

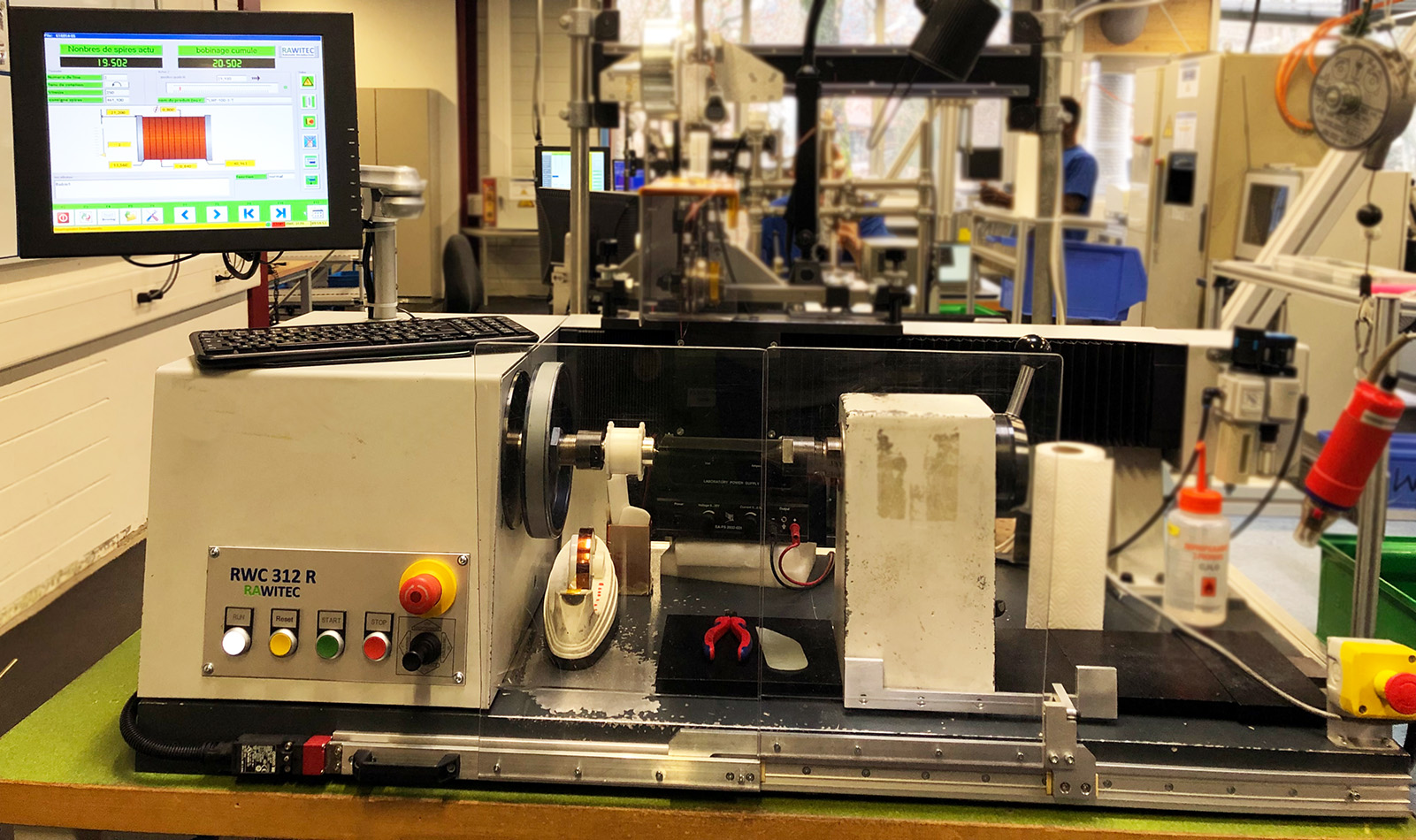

After – RWC312R Modernized / Retrofit Year 2017

After – RWC312R Modernized / Retrofit Year 2017

.wkz winding programs successfully converted

.wkz winding programs successfully converted

|

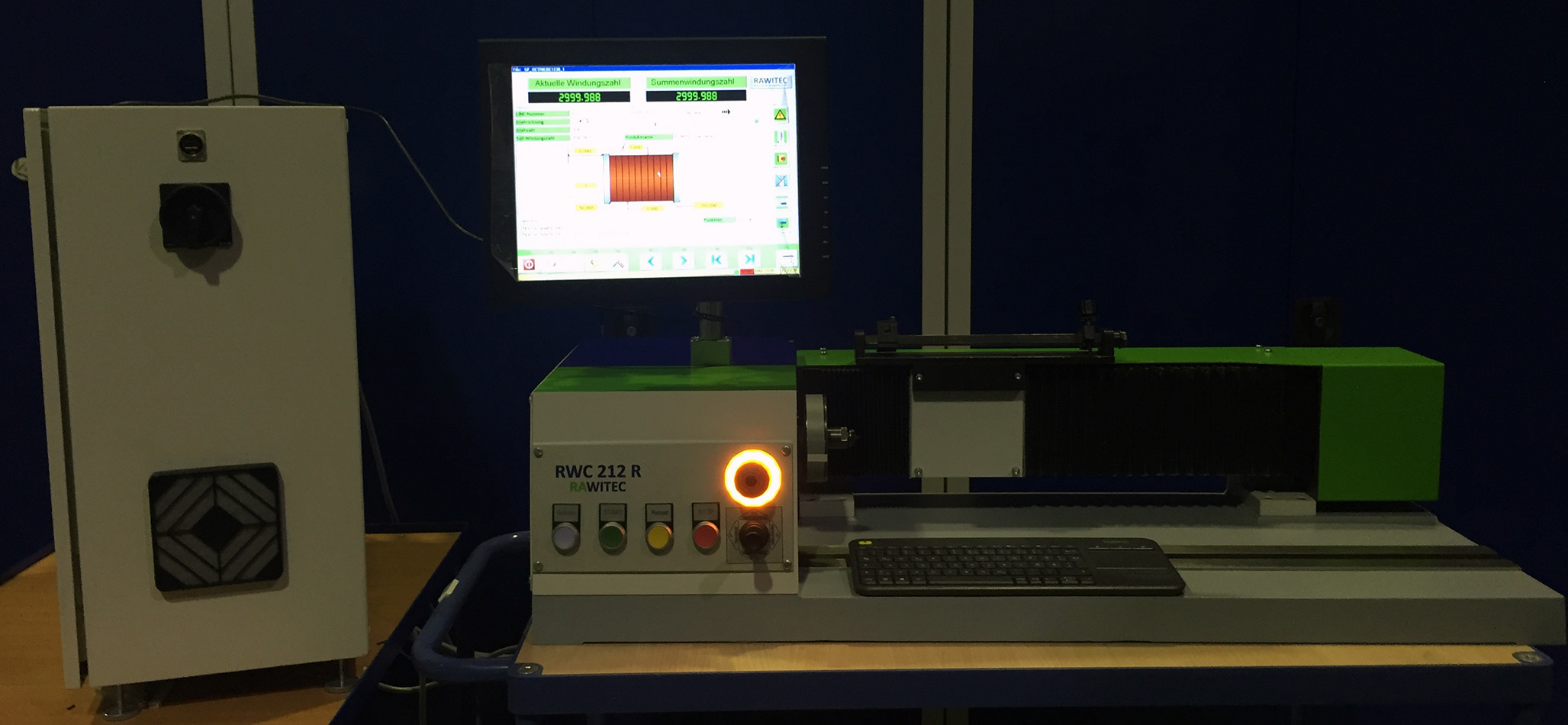

Retrofit Example: FW212G, Year 1998 – formerly IWT Industrielle Wickeltechnik GmbH

- Replacement of the complete power unit including old electronics and CNC control

- Existing winding programs converted from database to new PC format

- .wkz winding programs successfully transferred to modern control platform

- LCD display replaced by 15" touchscreen for better usability

- New joystick for precise manual axis control

- Safety relays for compliant and safe machine operation

- Existing winding tools can still be used

- Old software replaced by modern, intuitive user interface

- Program storage via USB, industrial PC or network

- Extended functions – saves time and reduces operating costs

Before FW212G / Year 1998

Before FW212G / Year 1998

|

After – RWC212G-R Modernized / Retrofit Year 2017

After – RWC212G-R Modernized / Retrofit Year 2017

After – RWC212G-R Modernized / Retrofit Year 2017

After – RWC212G-R Modernized / Retrofit Year 2017

.wkz winding programs successfully converted

.wkz winding programs successfully converted

|

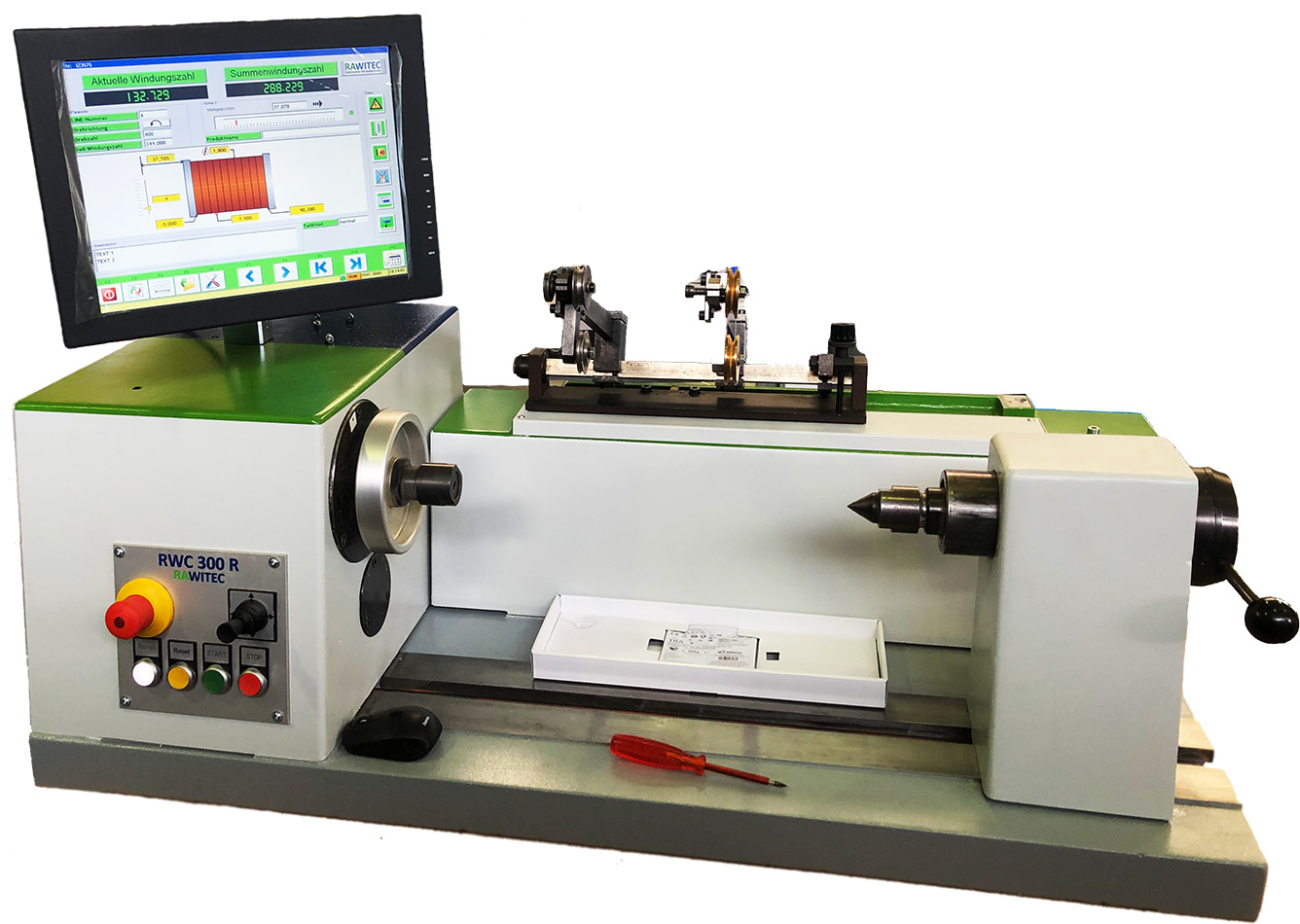

Retrofit Example: FW301, Year 2003 – formerly FAG / Frieseke & Hoepfner

- New control cabinet with modern servo drives

- LCD replaced by 15" touchscreen for enhanced usability

- .wkz winding programs transferred and integrated into new control system

- New joystick for manual axis control

- Software modernized with intuitive user interface

- Programs stored via USB or network

- Original winding functions maintained

- Expansion with additional axes and options possible

- Investment protection and efficiency increase

Vorher FAG FW300/ Year 1978

Vorher FAG FW300/ Year 1978

|

After – RWC301-R Modernized / Retrofit Year 2023

After – RWC301-R Modernized / Retrofit Year 2023

After – RWC301-R Modernized / Retrofit Year 2019

After – RWC301-R Modernized / Retrofit Year 2019

After – RWC301-R Modernized / Retrofit Year 2024

After – RWC301-R Modernized / Retrofit Year 2024

|

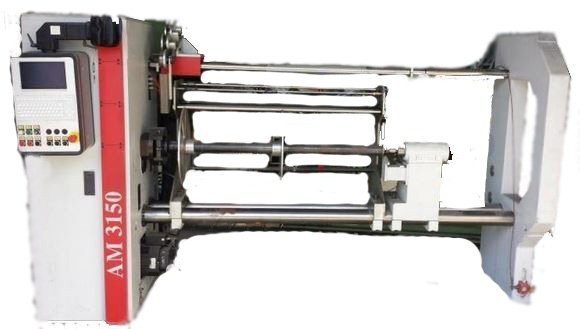

Retrofit Example: AM3150 – formerly Blume & Redecker

- Replacement of complete drive and control system

- Integration of existing winding programs in .wkz format

- Safety features and compliance with latest standards

- Continued use of mechanical parts and winding tools

- Upgrade to modern 15" touchscreen interface

- USB and network-based program storage

- Enhanced usability and software upgrades

- Energy-efficient drives reduce consumption

- Cost-effective modernization extends service life

Befor BR AM 3150/ Year 1998

Befor BR AM 3150/ Year 1998

|

After – AM3150 Modernized

After – AM3150 Modernized

|

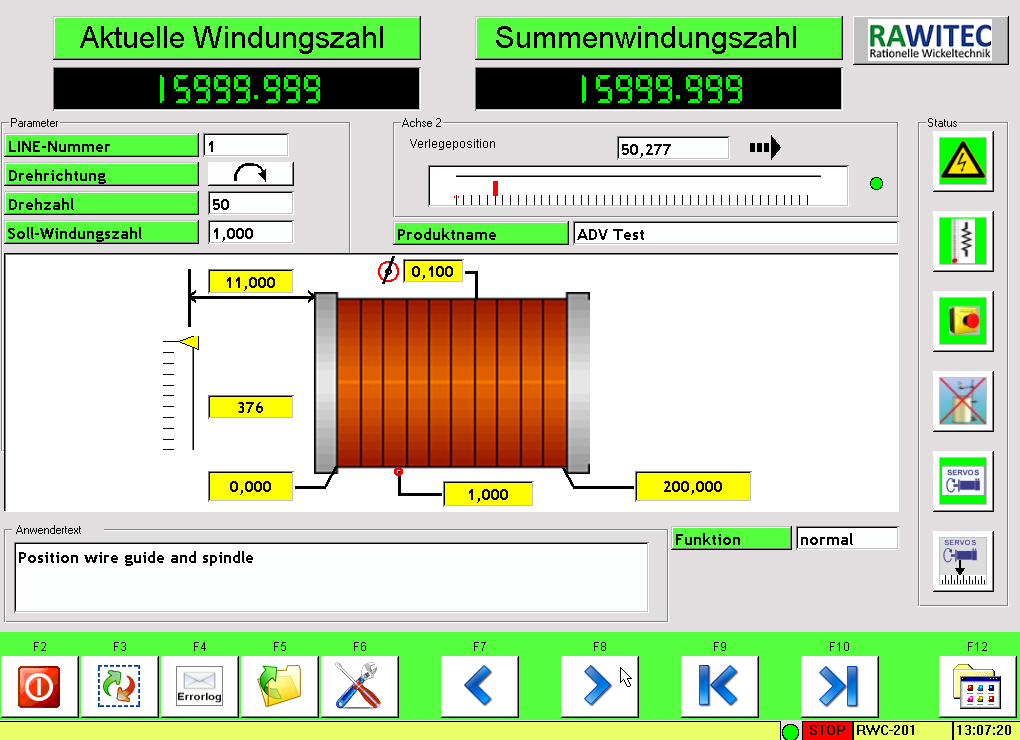

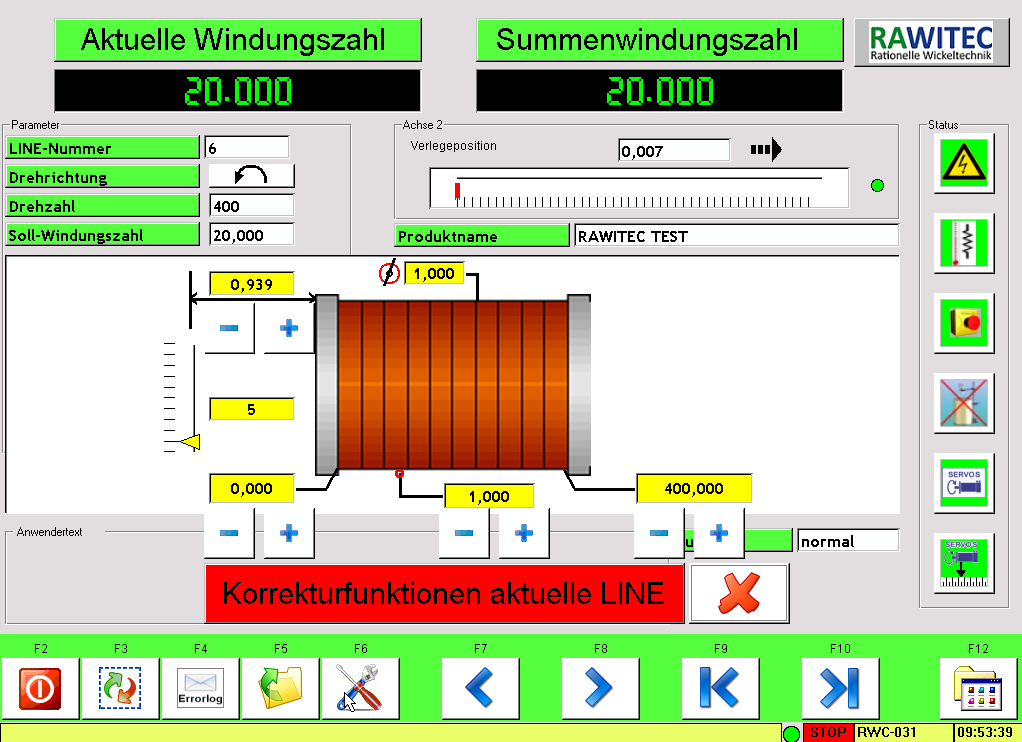

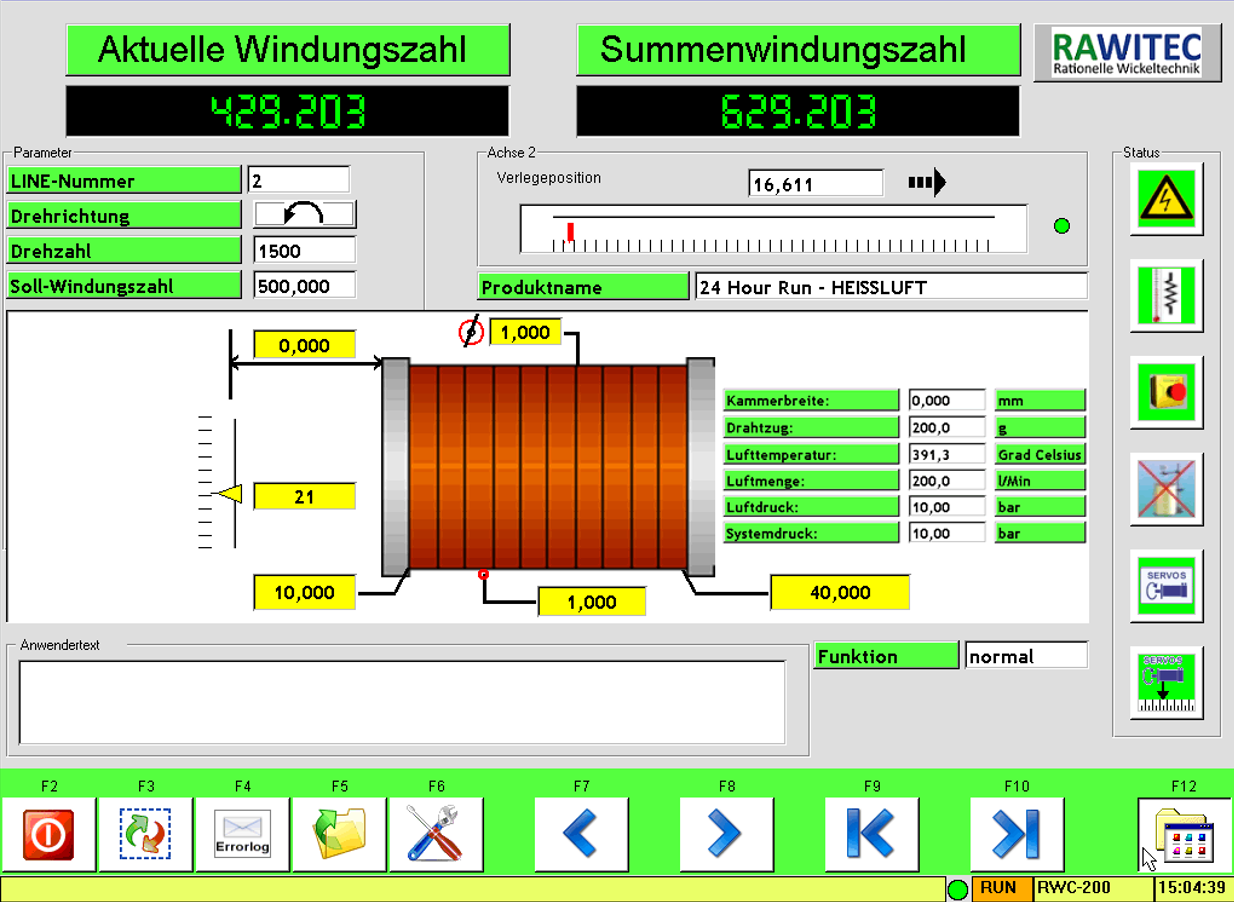

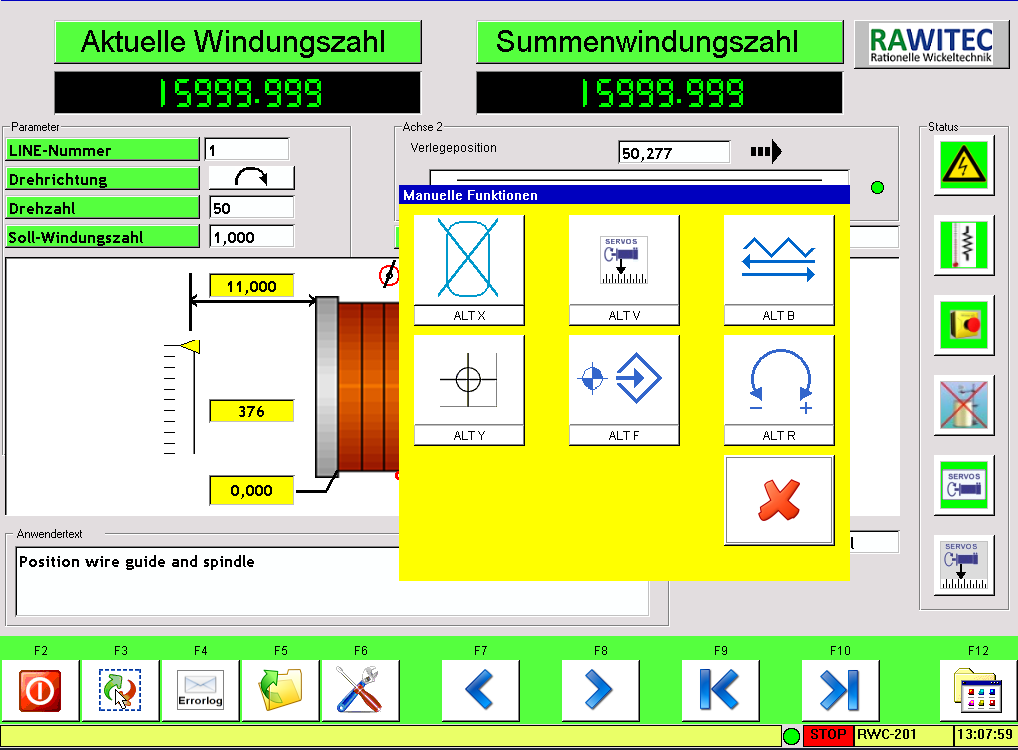

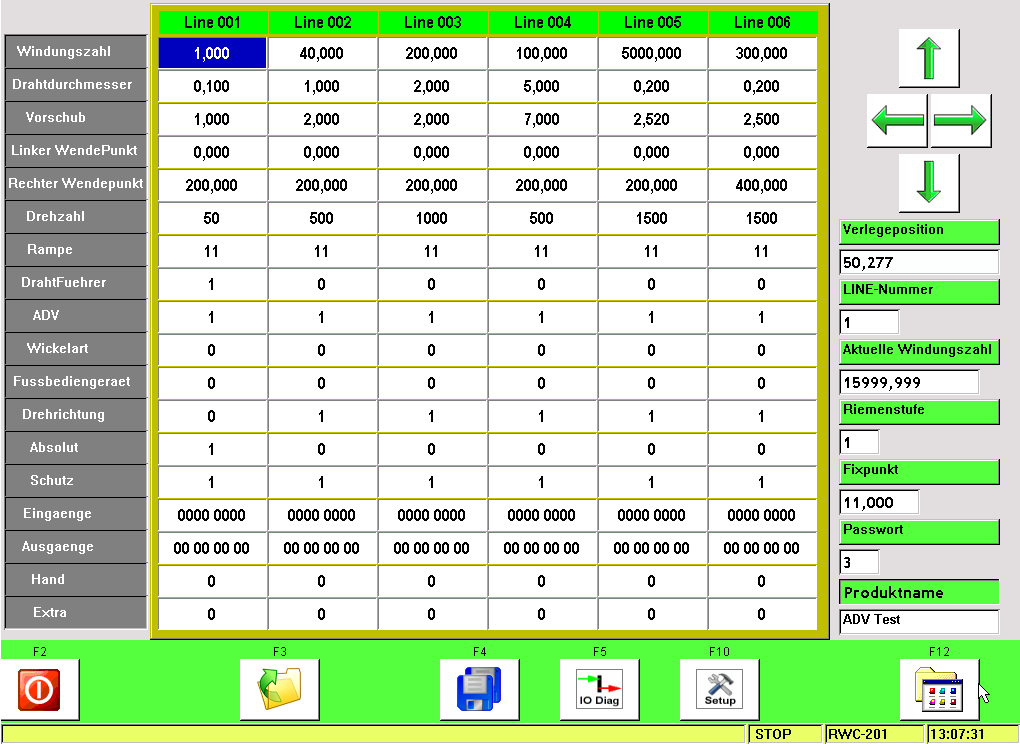

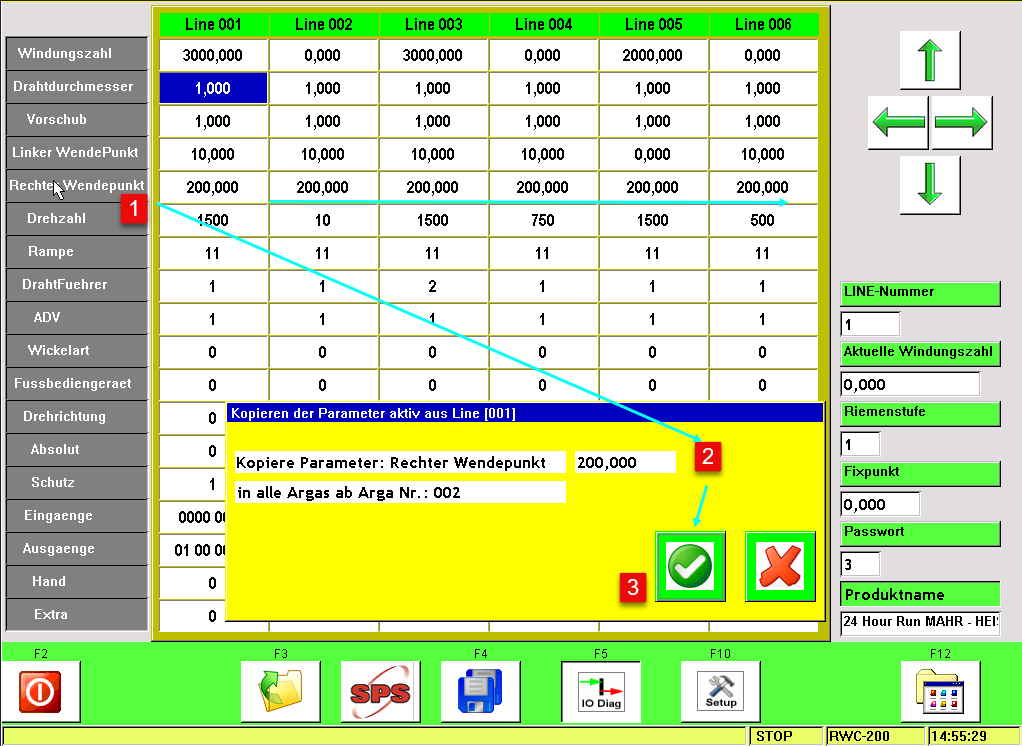

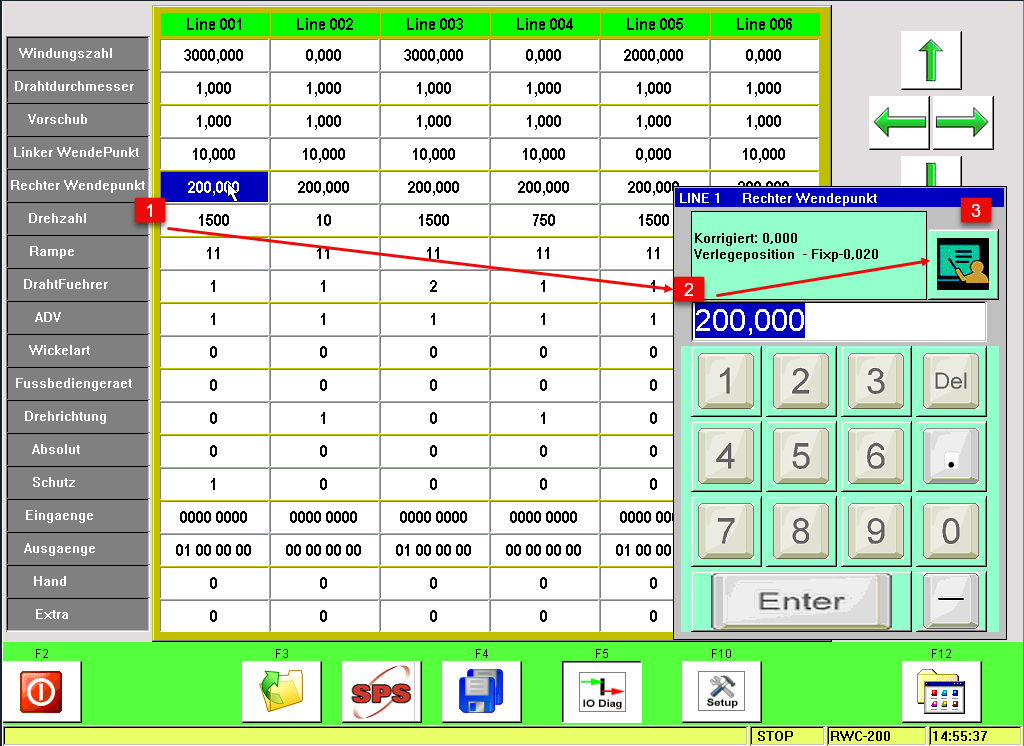

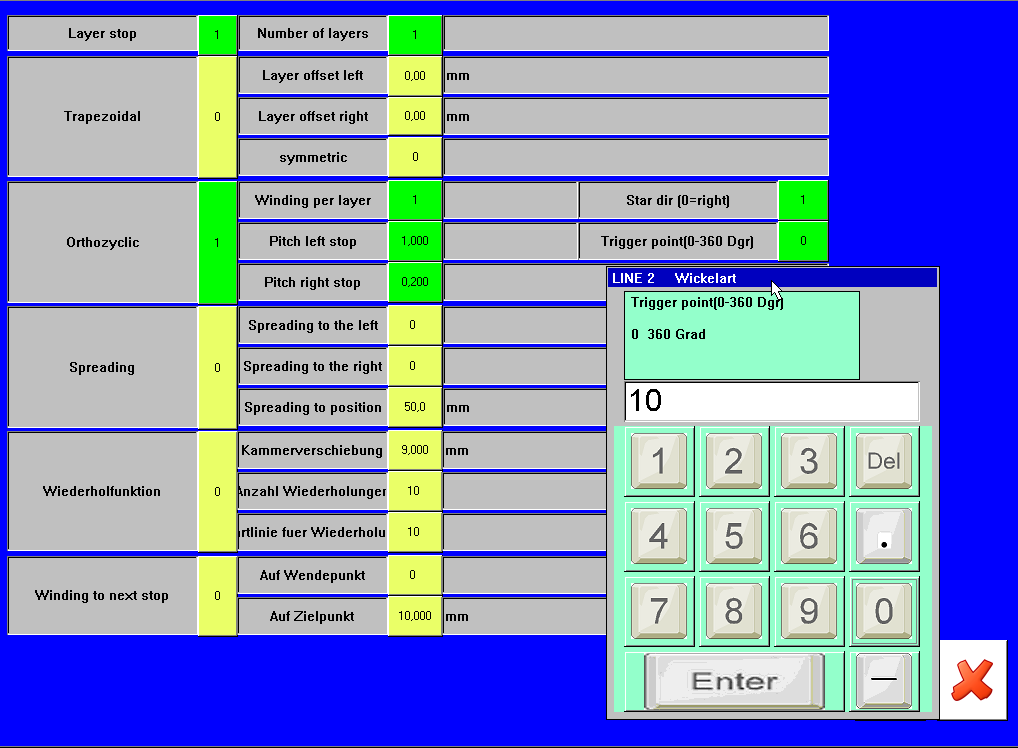

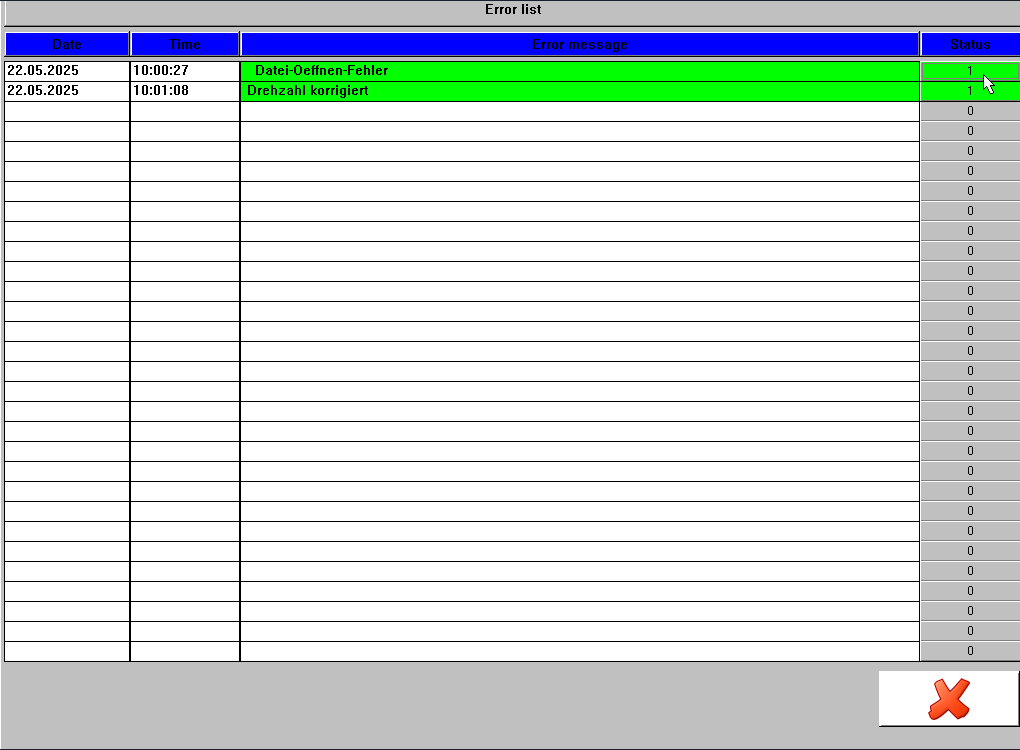

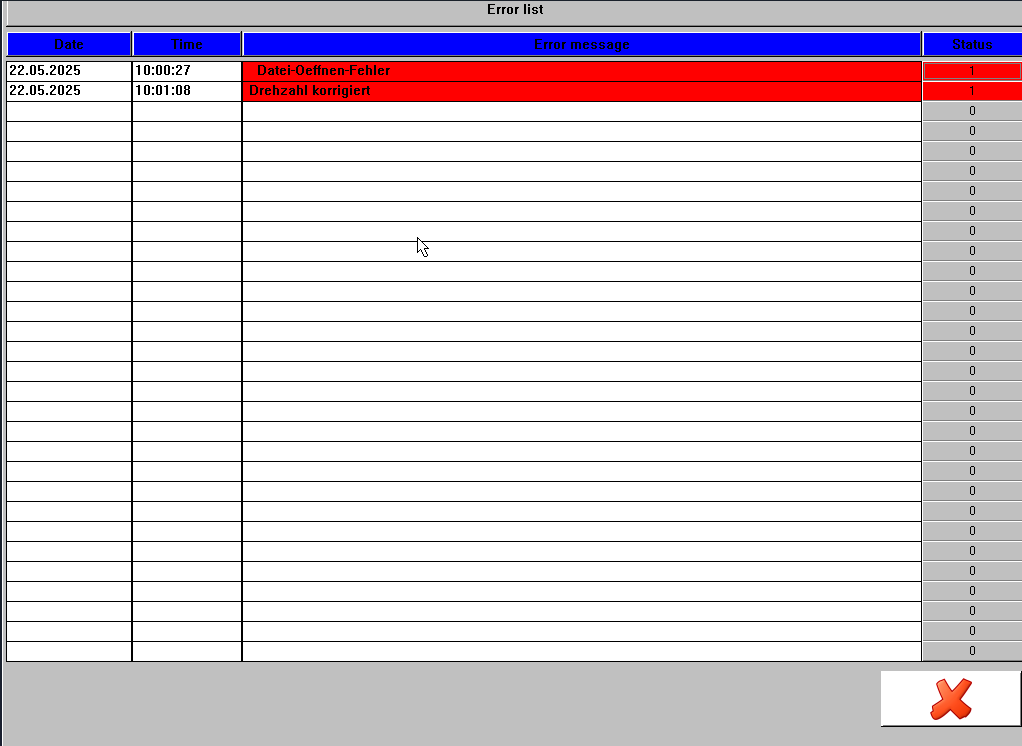

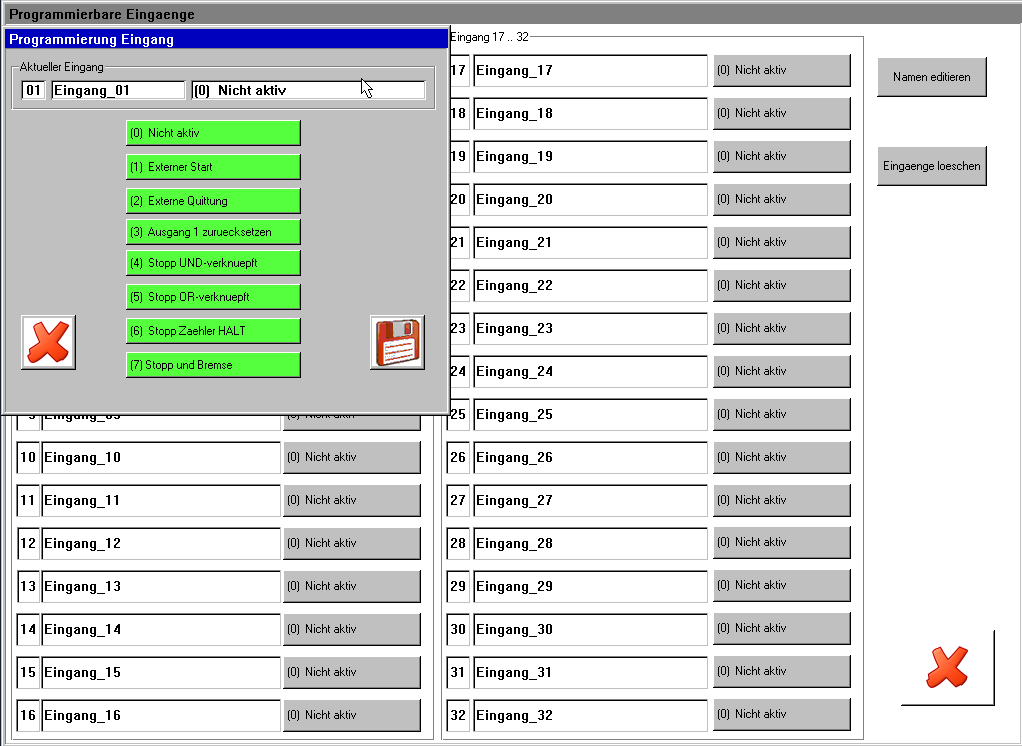

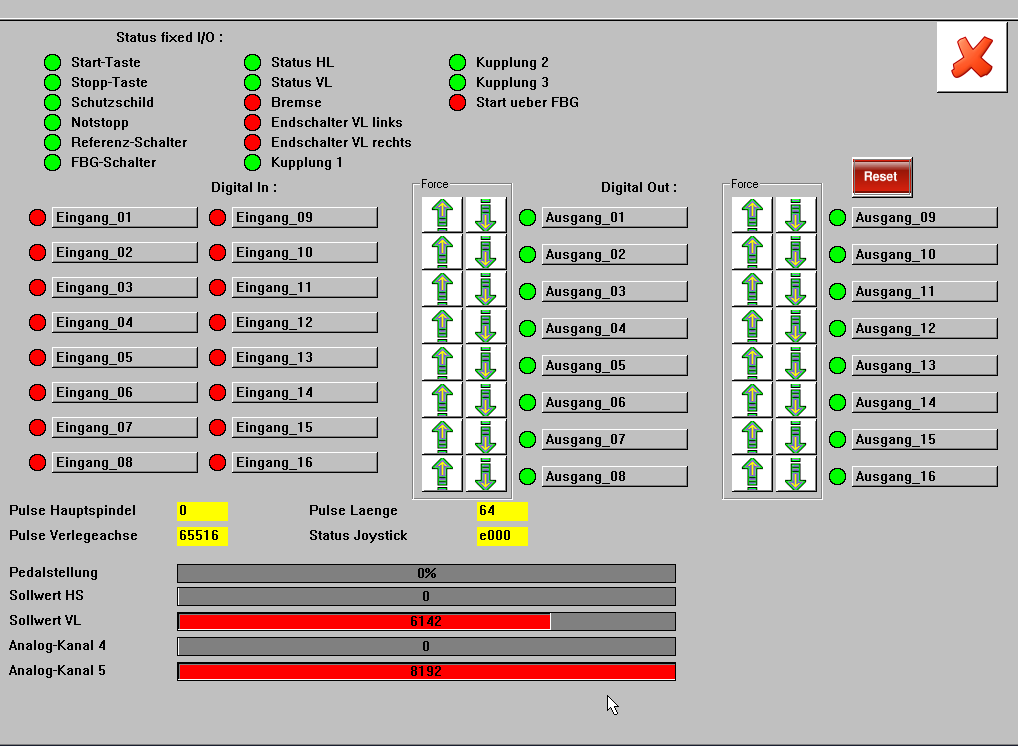

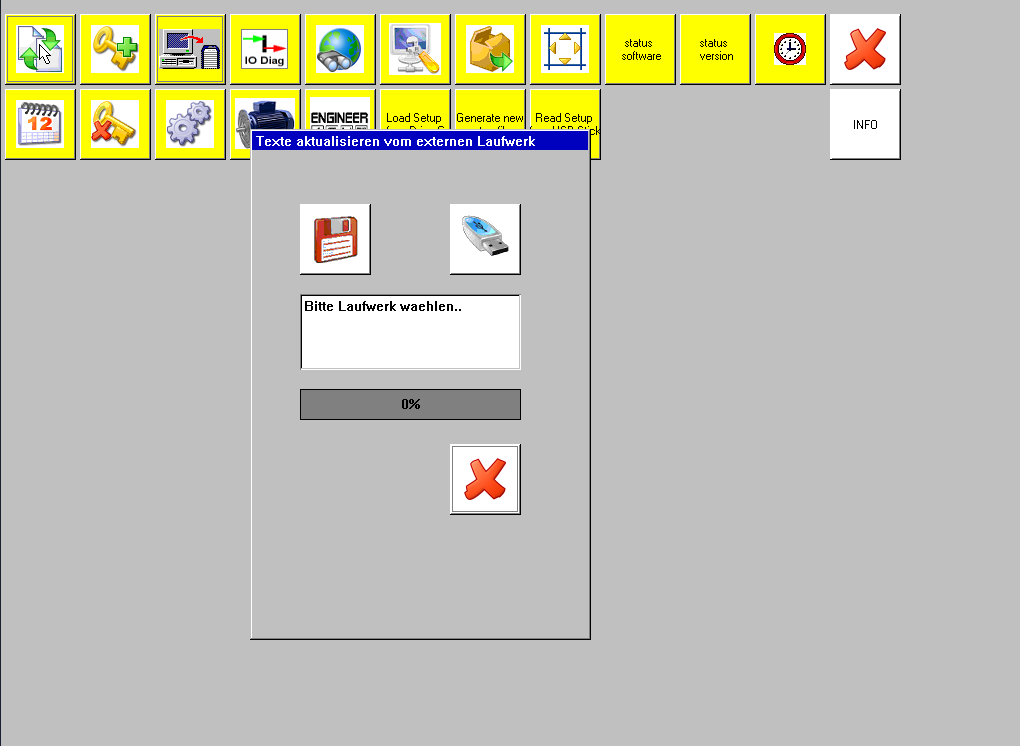

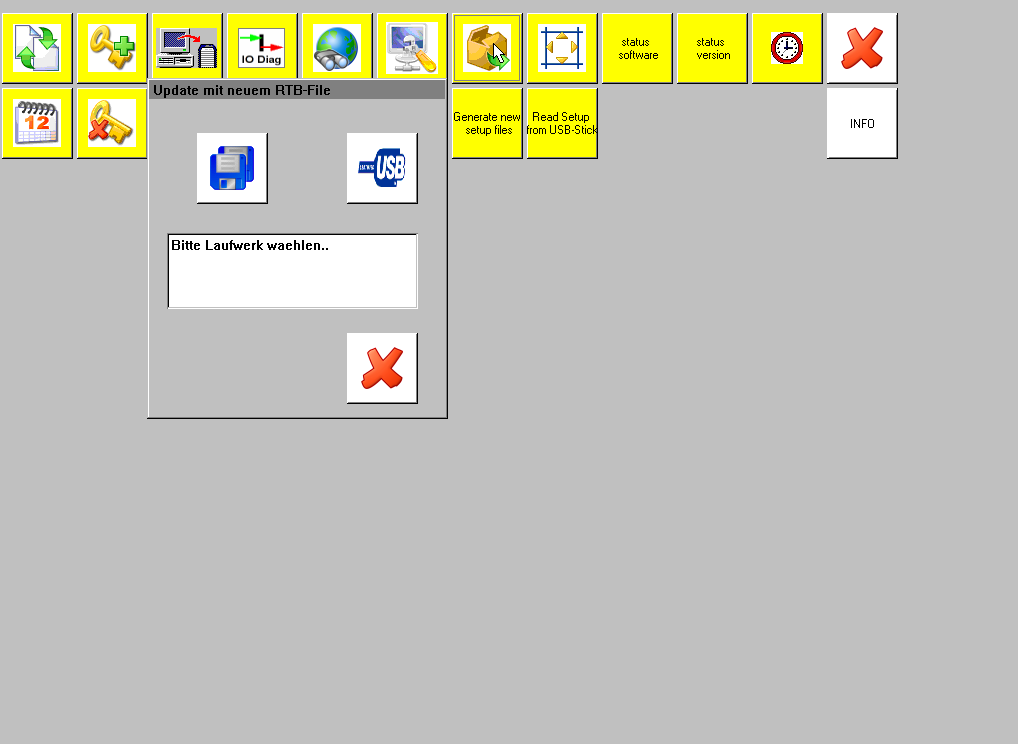

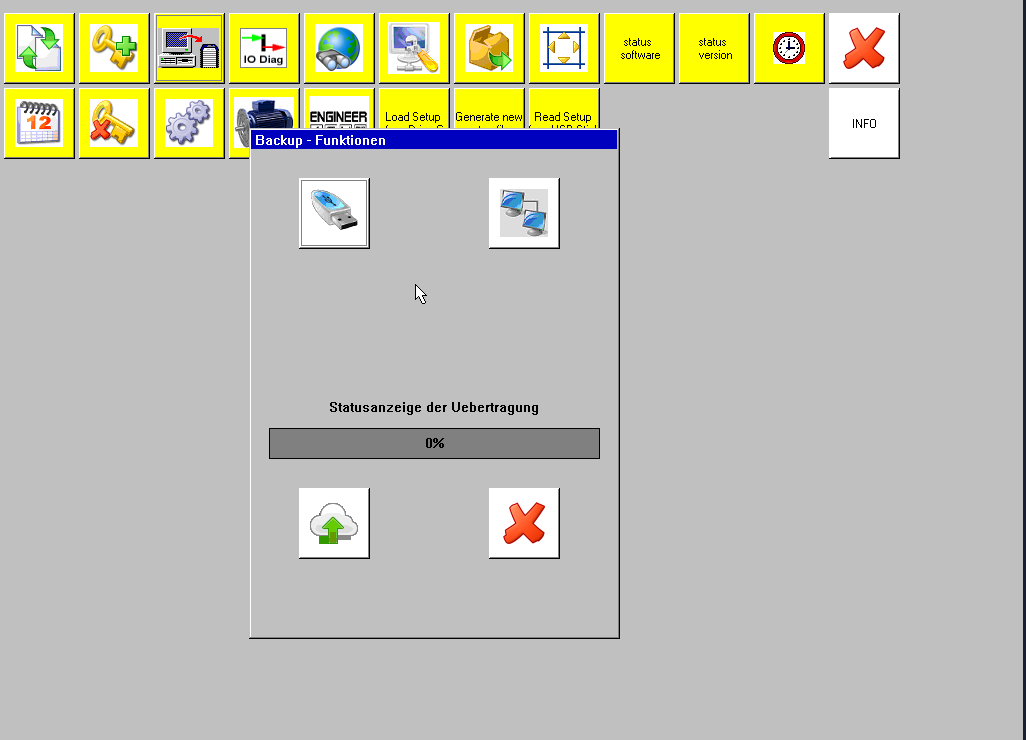

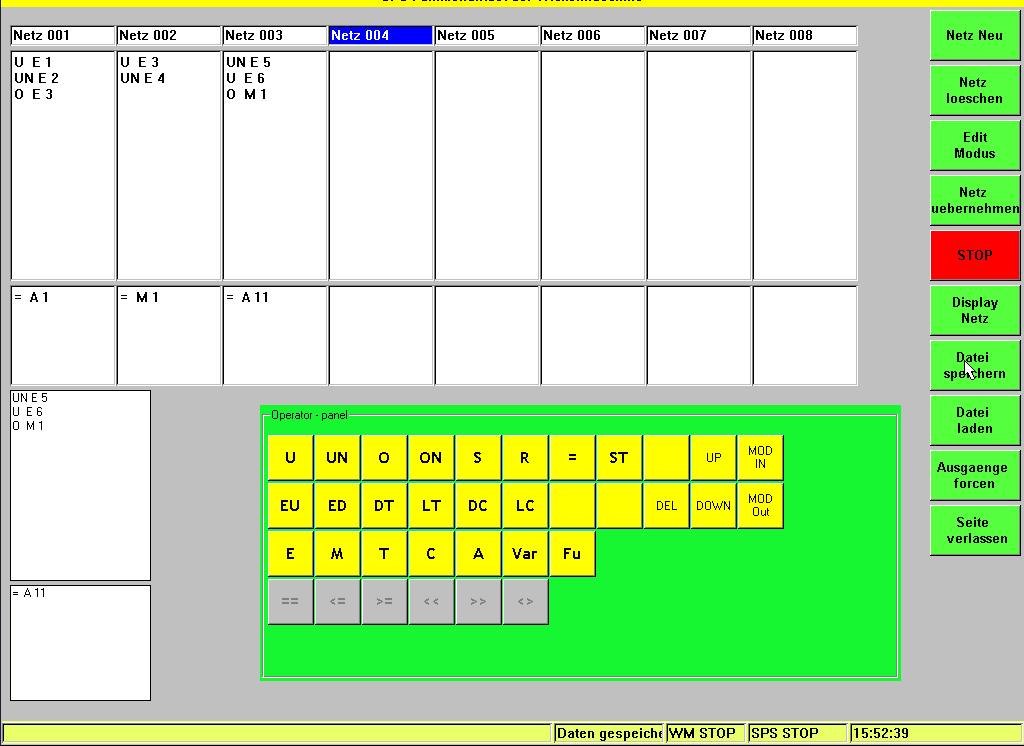

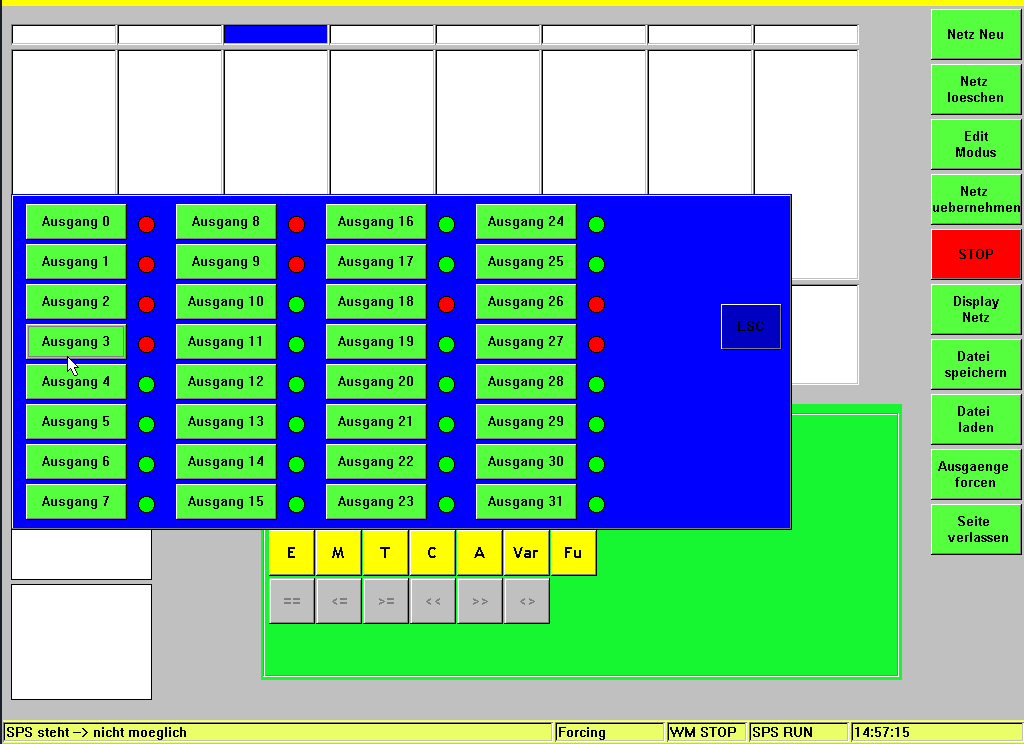

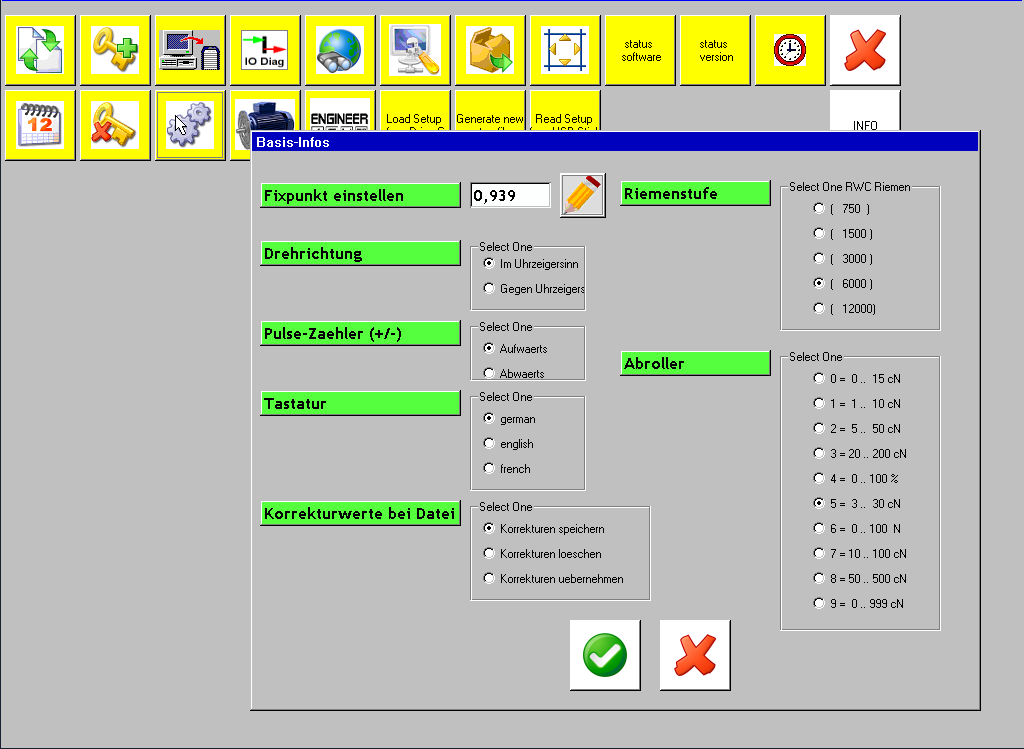

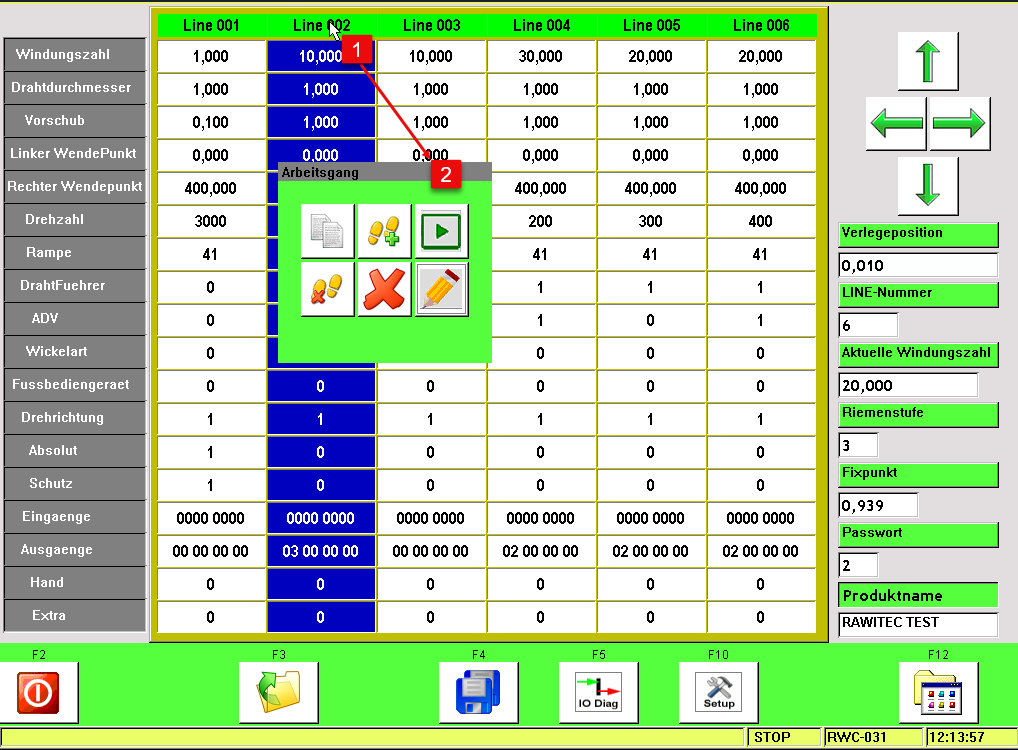

Intuitive Touch Software for Winding Machines – Powerful & Versatile

The user interface was specially developed for intuitive and efficient touch operation on winding machines.

In addition to essential functions such as Open, Save, Copy, Delete, Edit, and Print winding programs, the software offers numerous advanced features:

- Integrated language switch for international use

- Extensive configuration options

- Service-relevant diagnostic tools

- Tools for system optimization and machine customization

Thanks to its clearly structured interface, the software supports both machine operators in daily production and technical staff during machine configuration and customization.