🌀 RWC801-AITE

High-tech automatic winder for medium-voltage instrument transformers

Efficiency meets precision: the RWC801-AITE is engineered for fully automatic production of primary coils. It combines robust mechanics, smart control, and maximum flexibility.

🚀 Key benefits at a glance

- Up to 6 coils in parallel – higher output, less time

- Dual winding supported – two wires per coil

- Electronic wire brakes – constant, programmable wire tension

- Automatic insulation feed – dancer control, cross-cut unit & monitoring

- RTOS-32 & EtherCAT control – remote service, 21.5″/24″ touch panel

📦 Smart insulation feed

Precise. Flexible. Automatic.

- Pneumatic expanding shaft for supply rolls (Ø 60–78 mm)

- Dancer control for smooth film transport

- Cross-cut unit for millimetre-accurate length cutting

- Material monitoring & automatic winding growth compensation

🎚️ Wire guidance & brakes

Full control over the wire.

- 2–6 wire guides, AC servo drive

- Parallel dual winding possible

- Programmed wire tension – electronically regulated

- 4 electronic wire brakes (125–600 g), expandable to 6

✂️ Cutting & trimming

Clean edges – automatically.

- Radially adjustable knives

- Automatic cutting after defined layers

- Trimming after the winding process – no residual material co-wound

- Flexibly adjustable knife spacing

⚙️ Optional innovations

- Parallel winding of 5–6 coils

- Automatic knife adjustment (step cut)

- Longitudinal cutting module for insulation material

- Automatic spacing adjustment of the wire brakes

- Gluing/fixing device for crepe & cable paper

- Weight measurement up to 150 kg (5 g / 10 g steps)

- LED workspace lighting

📊 Technical highlights

- Wire diameter: 0.10–0.40 mm

- Coil width: up to 995 mm

- Winding diameter: max. 1060 mm

- Winding weight: up to 150 kg

- Drive power: 13.2 kW

- EtherCAT I/O: up to 640 channels, 16 axes

- Dimensions: 2650 × 1900 × 2100 mm

- Machine weight: approx. 3250 kg

* Values from data sheet. Subject to change. Colors: RAL 5002 Ultramarine Blue / RAL 6018 Yellow Green / RAL 7035 Light Grey HR.

❓ Is the RWC801-AITE the right fit for you?

We advise on parallel/dual winding, insulation setup, options, and cycle time.

| Technical Specifications | |||

| Machine type | RWC801-AITE* | ||

| Wire diameter | mm | 0.1 – 0.4 | |

| Traverse width | mm | 1330 * | |

| Wire traverse | mm | 800 | |

| Clamping length | mm | 1300 * | |

| Max. feed / traverse | mm | 99 per spindle revolution ³ | |

| Belt ratio | 0 – 1 | ||

| Belt stage 0 – speed | rpm | max. 750 | |

| Belt stage 0 – torque | Nm | max. 168 | |

| Belt stage 1 – speed | rpm | max. 1500 | |

| Belt stage 1 – torque | Nm | max. 84 | |

| Drive power | kW | 13.2 | |

| Coil width | mm | 70 – 160 | |

| Insulation width | mm | max. 1060 | |

| Insulation thickness | mm | 0.05 – 0.12 *** | |

| Compressed air | bar | 6–7, dry and oil-free | |

| Noise level | dB(A) | < 70 | |

| Tailstock center height / swing diameter | mm | 995 / 400 * | |

| Winding diameter | mm | 55 – 250 *** | |

| Winding weight | kg | max. 150 (without mandrel) | |

| Color | Standard: RAL 5002 Ultramarine / RAL 6018 Yellow Green · RAL 7035 Light Grey HR (other combinations on request) | ||

| Interfaces & control | Industrial PC with single-core 1 GHz / 2 GB RAM; optional dual-core ** | ||

| Languages | DE, EN, AL, IT, FR, ES, CS, HU, SU, RU, PL, NL, EL, PT, ZH … *** | ||

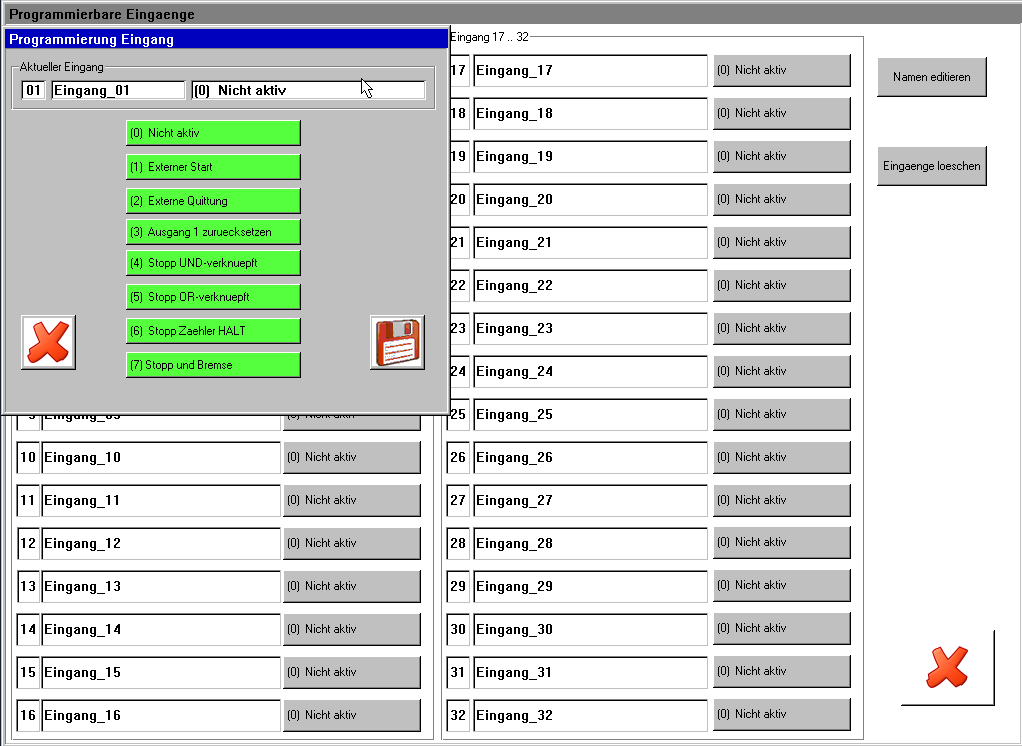

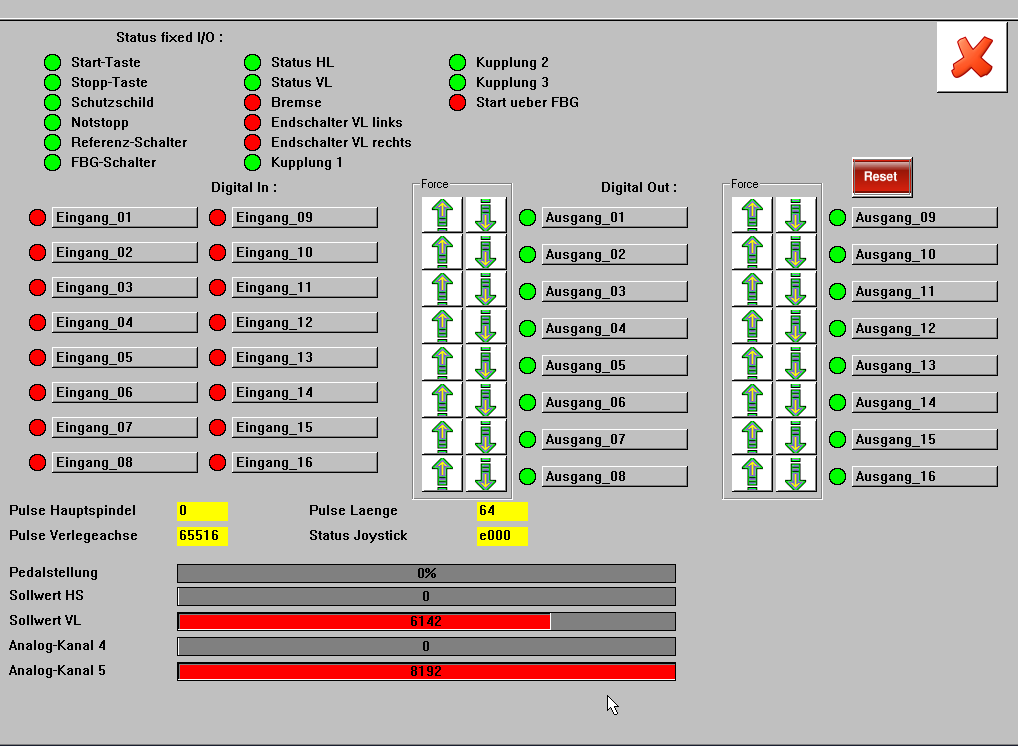

| Connections | USB: 2× USB 2.0 · Network: 2× Ethernet (100 Mbit) + 1× Gigabit · 2× RS-232 · VGA · foot pedal & joystick · Digital I/O: 16 freely programmable I/Os + 20 dedicated I/Os · 2× PS/2 · EtherCAT bus coupler · EtherCAT I/O up to 640 channels / max. 16 axes | ||

| OS | Robust real-time operating system with EtherCAT master | ||

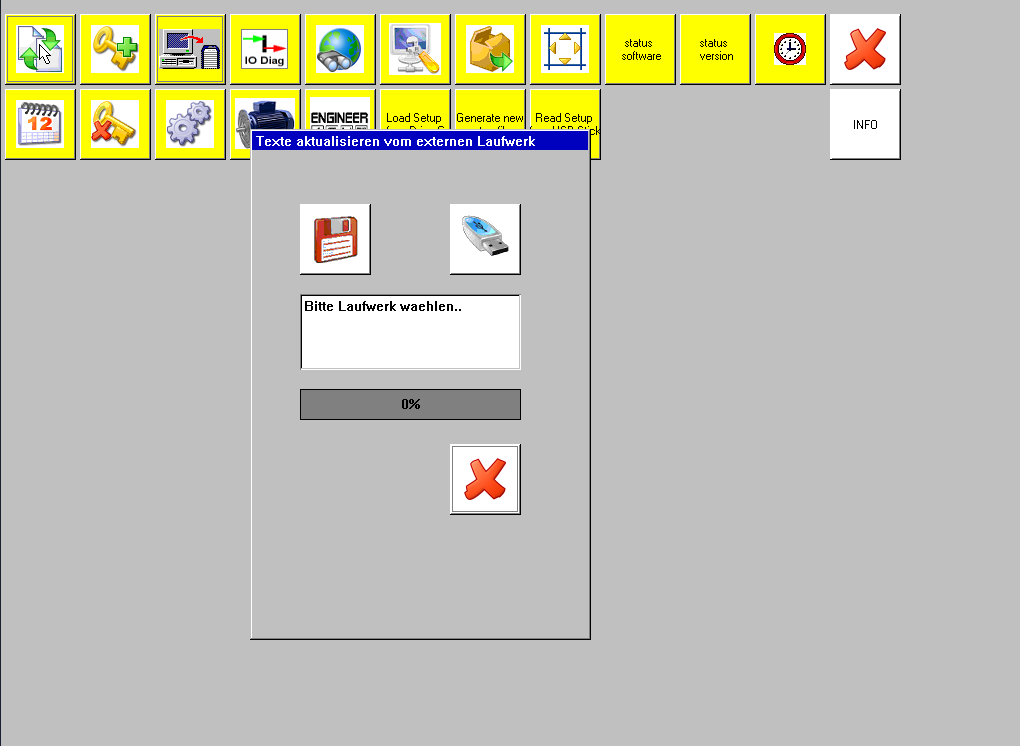

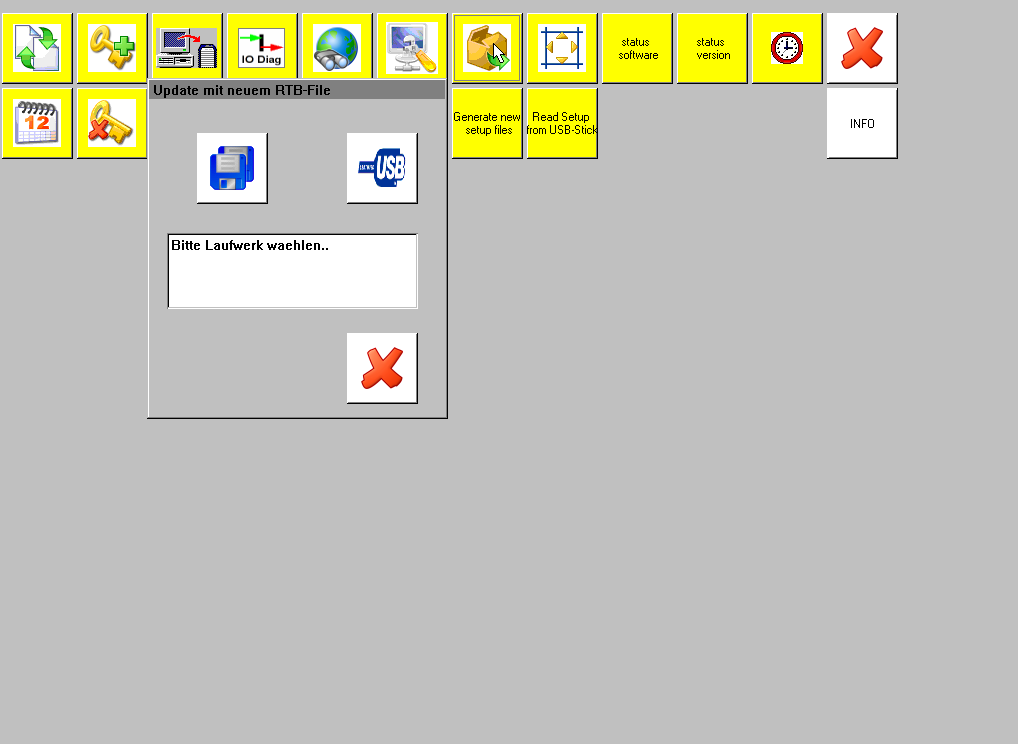

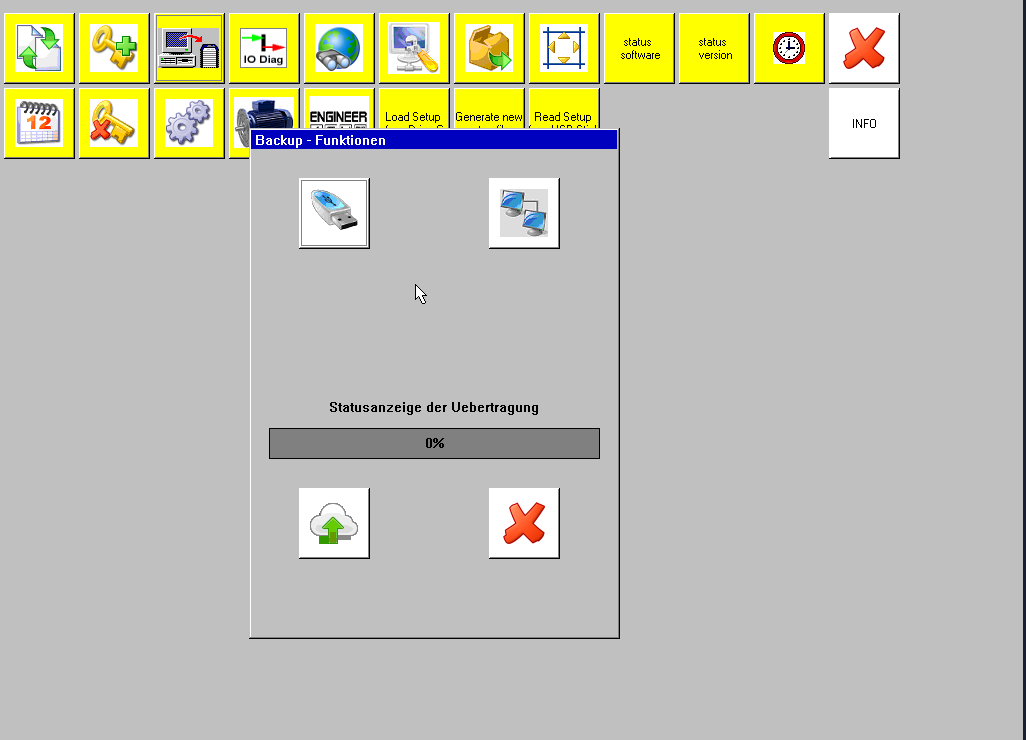

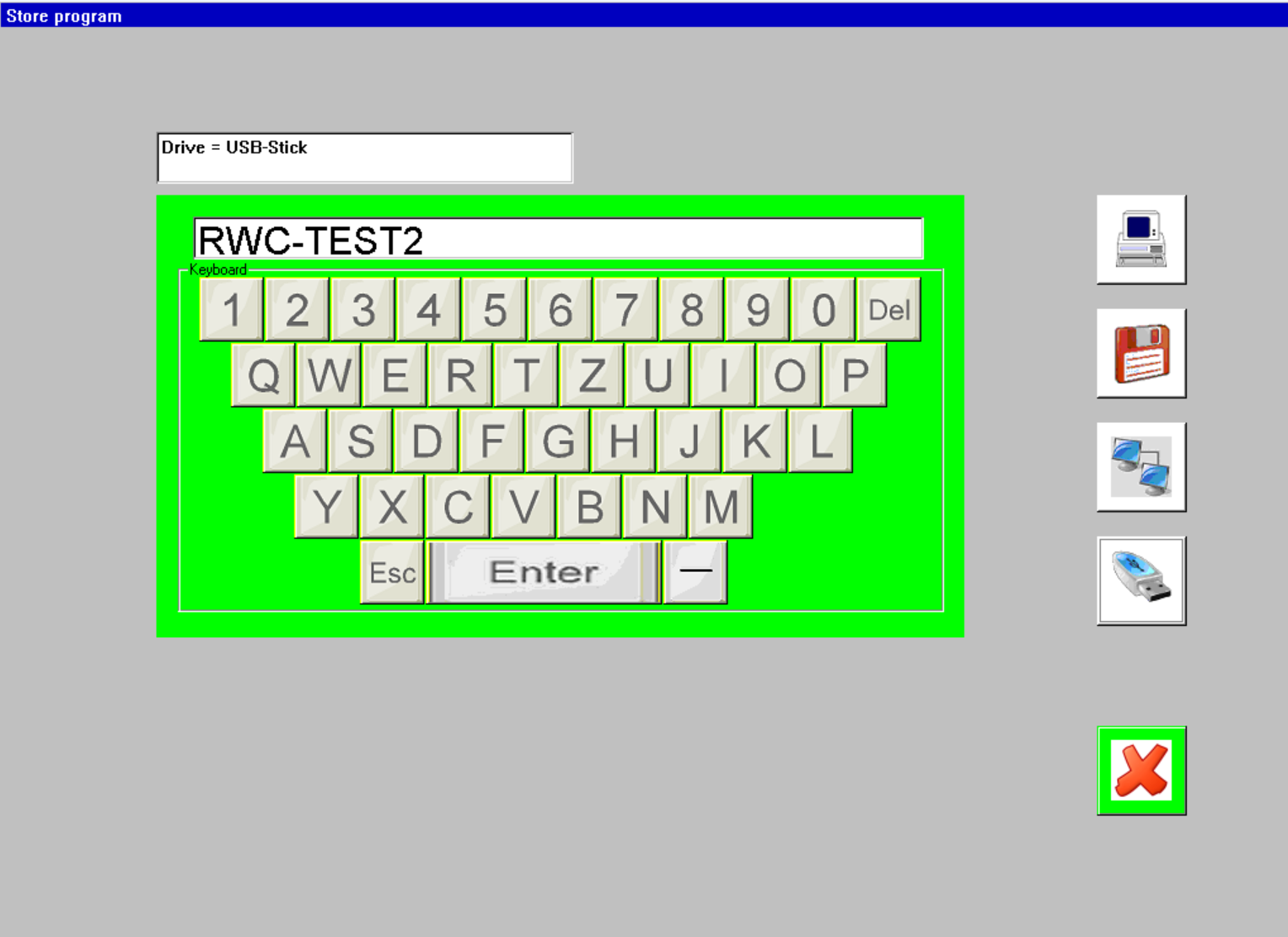

| Data backup / update | via USB and Ethernet | ||

| Printer (optional) | USB ** | ||

| Digital/analog I/O (optional) | expandable up to 640 I/O *** | ||

| Display | 21.5″ industrial touch screen (standard), 24″ optional ** | ||

| Keyboard | USB cable or 2.4 GHz wireless ** | ||

| Storage media | SATA-DOM 4 GB iSLC/iMLC (optional 8–128 GB **), flash; approx. 5,000 programs locally ², approx. 20,000 on network *** | ||

| Extensions | EtherCAT & PC interface for external control available (integrated) ** | ||

| Joystick | Teach function for manual axis control: spindle CW/CCW rotation, traverse left/right | ||

| Connected load | kVA | 22 | |

| Machine dimensions (W×D×H) | mm | 2650 × 1900 × 2100 | |

| Control cabinet dimensions | mm | approx. 1600 × 400 × 2000 | |

| Power supply | AC | 3× 400 V ±5 %, 50 Hz, approx. 22 kVA | |

| Weight | kg | approx. 3250 | |

* Specifications may vary; subject to change.

** Optional equipment.

*** Expandable on request.

² Approx. 400 kB (500 steps incl. comments).

³ Valid when spindle speed × feed < 3600/min.

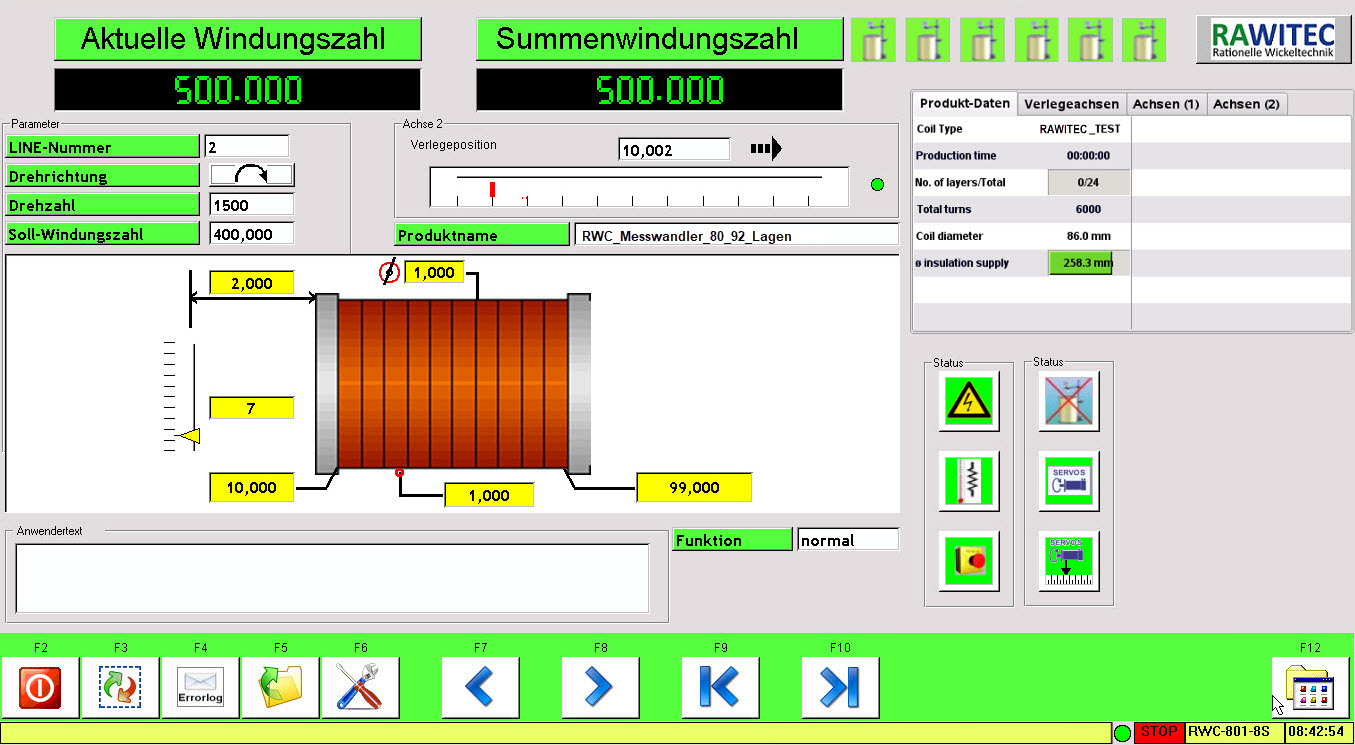

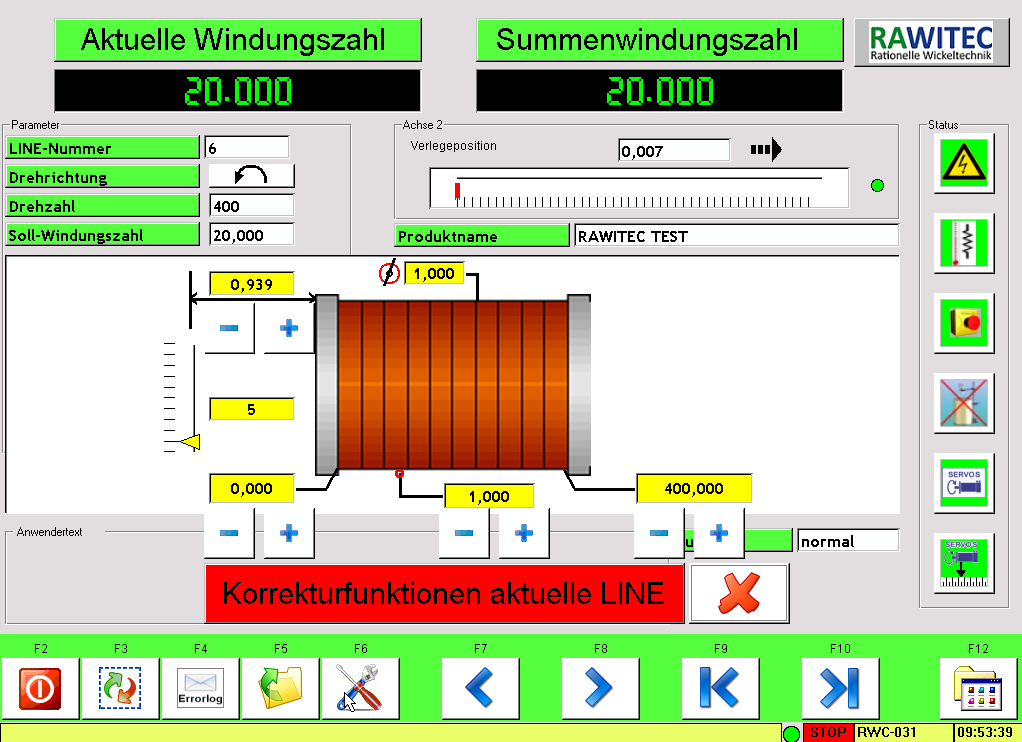

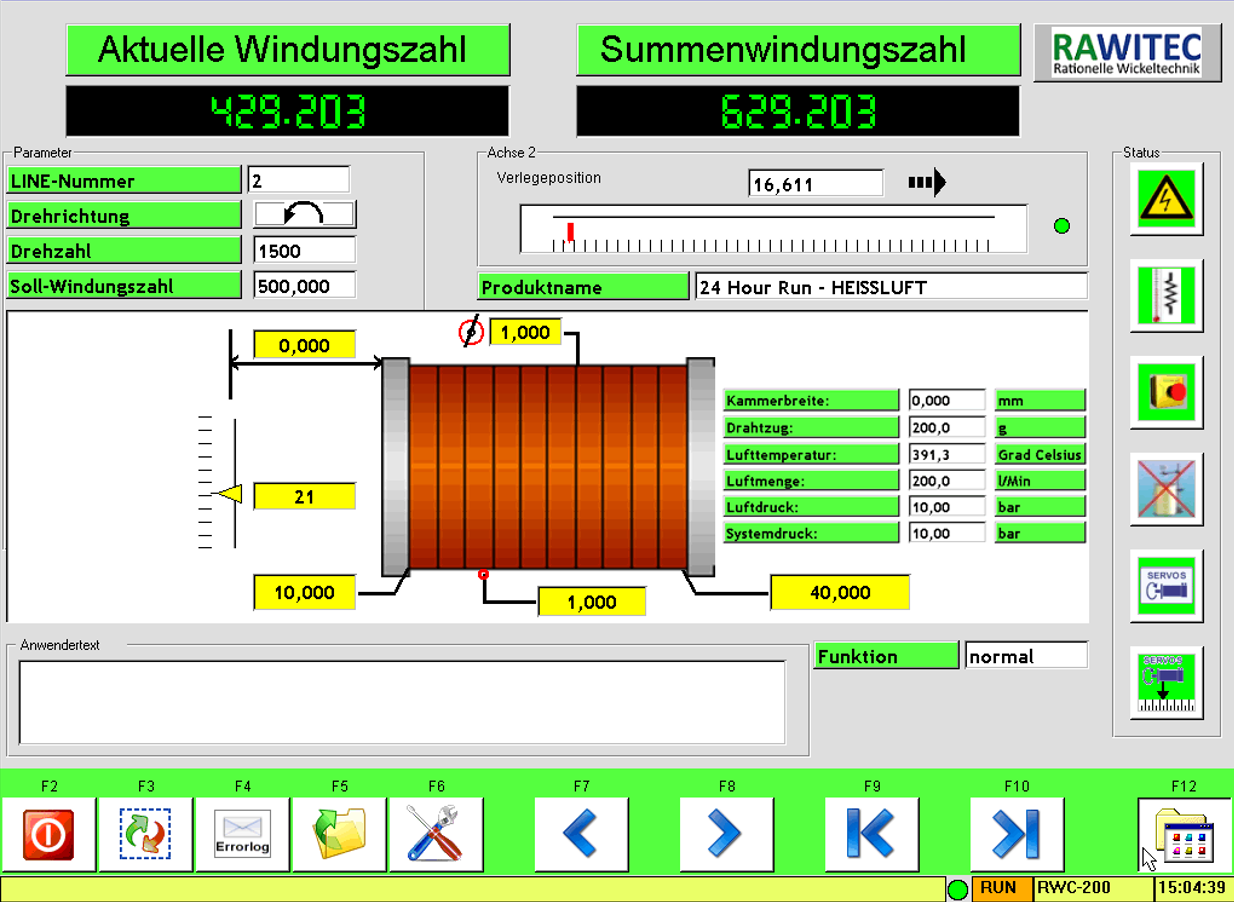

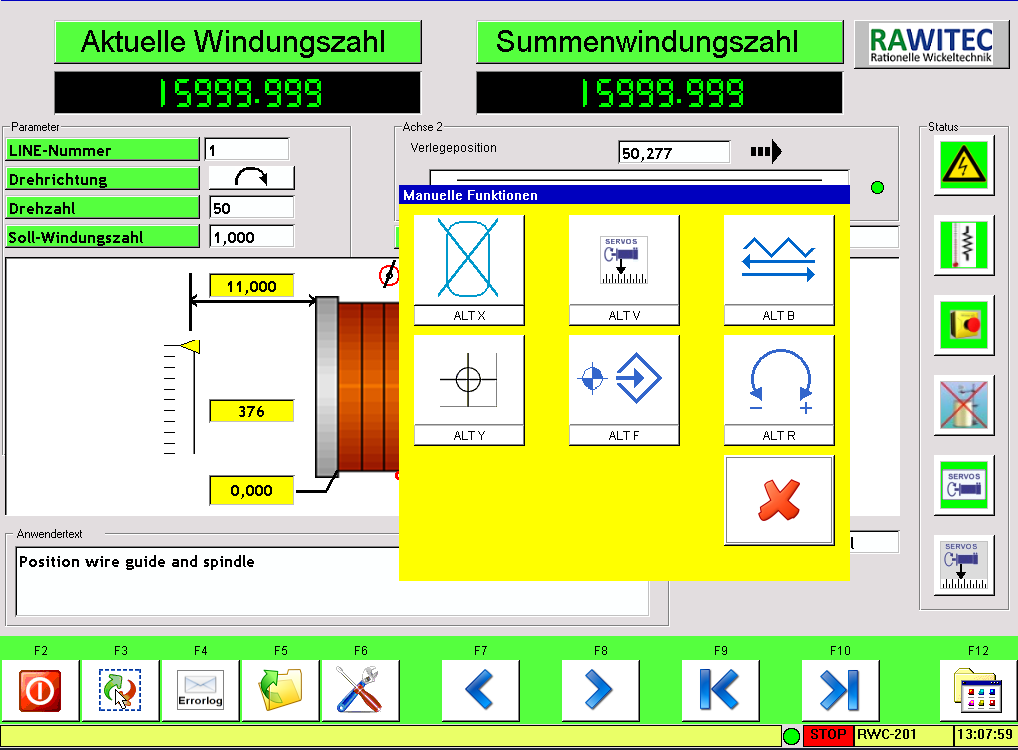

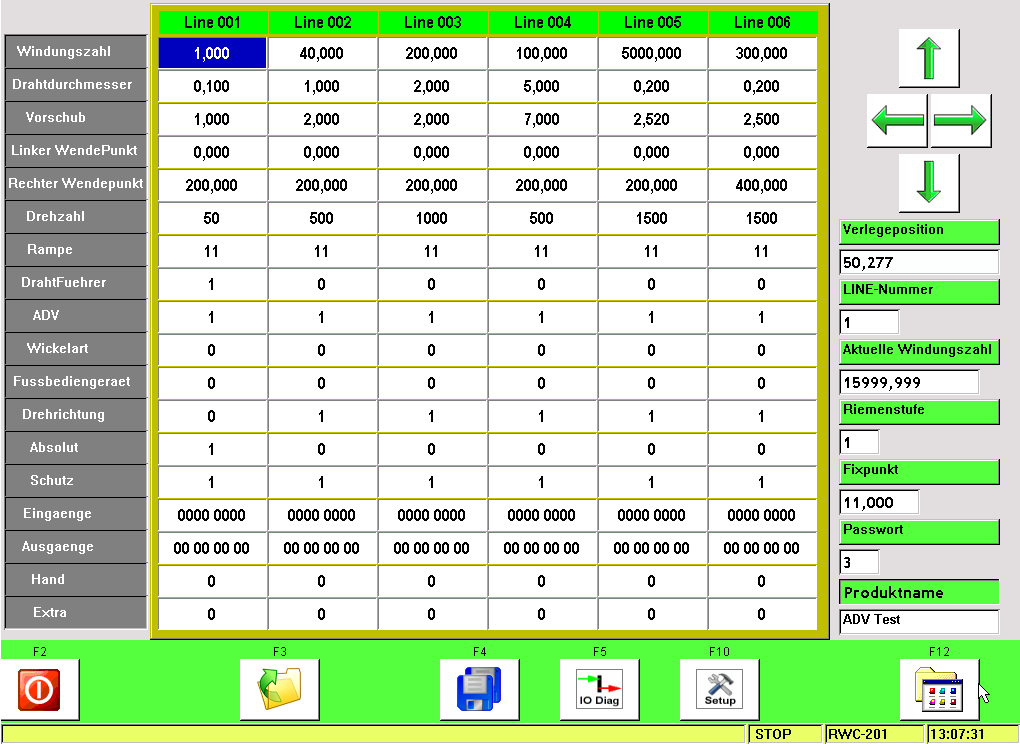

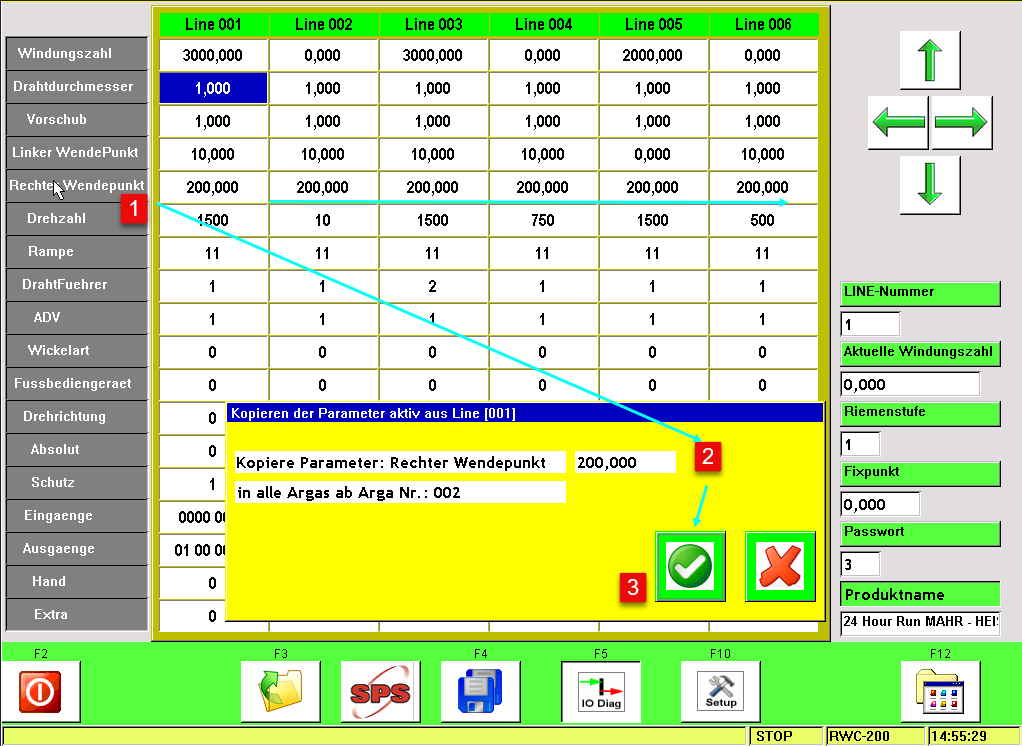

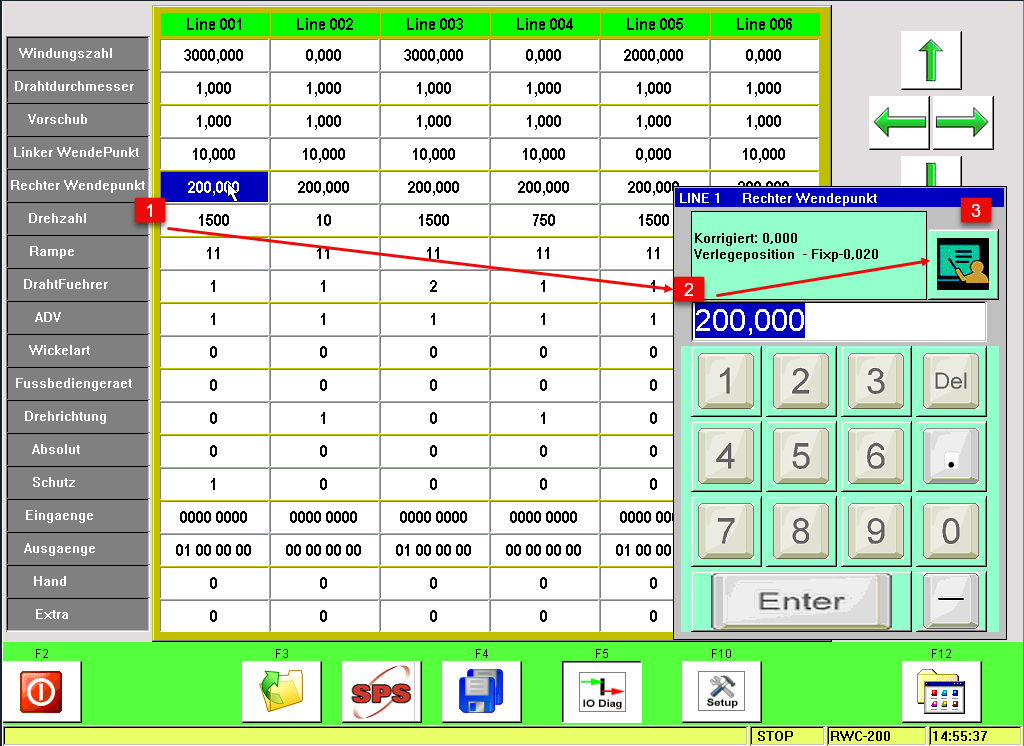

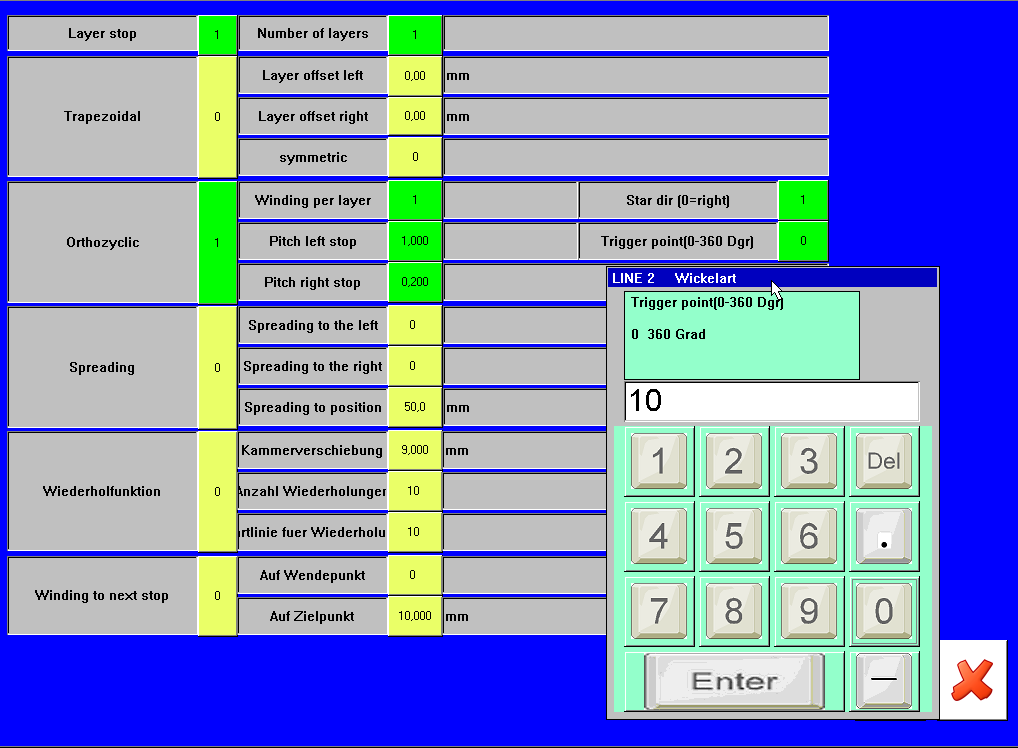

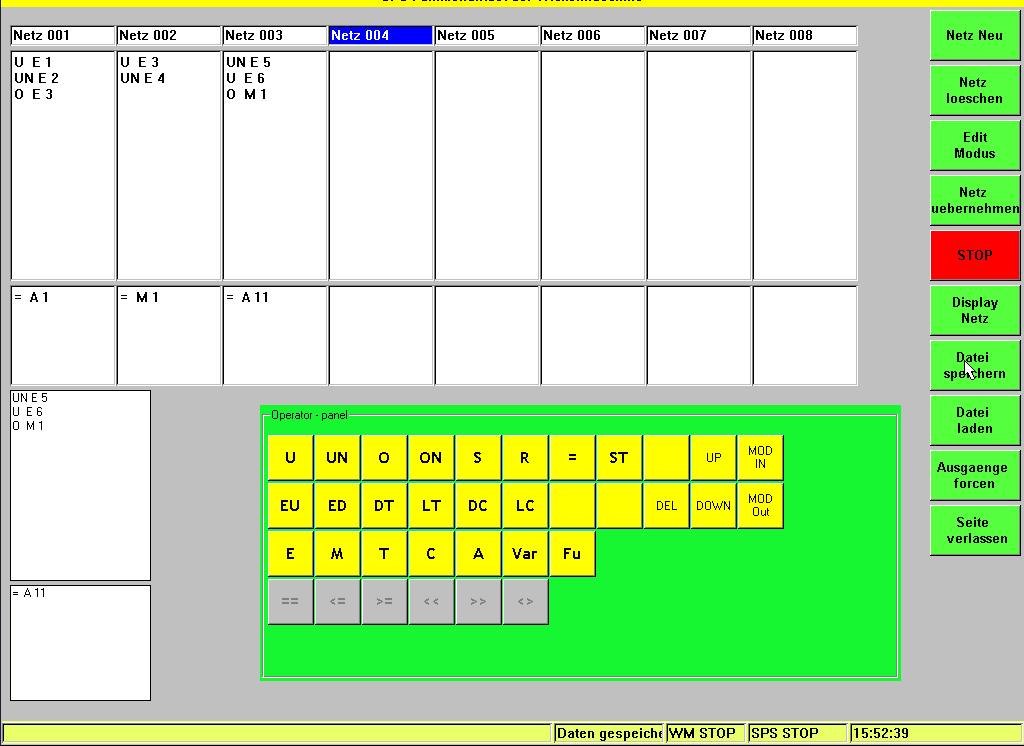

Intuitive Touch-Software für Wickelmaschinen – leistungsstark & vielseitig

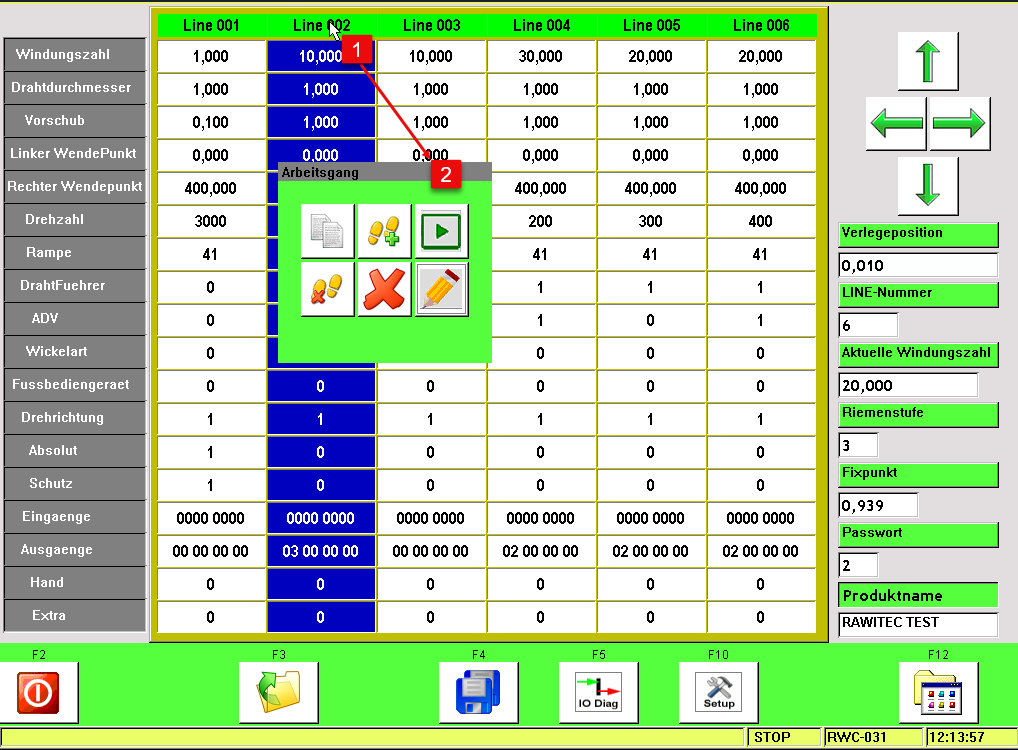

Die Benutzeroberfläche wurde speziell für die einfache und effiziente Touch-Bedienung an Wickelmaschinen entwickelt.

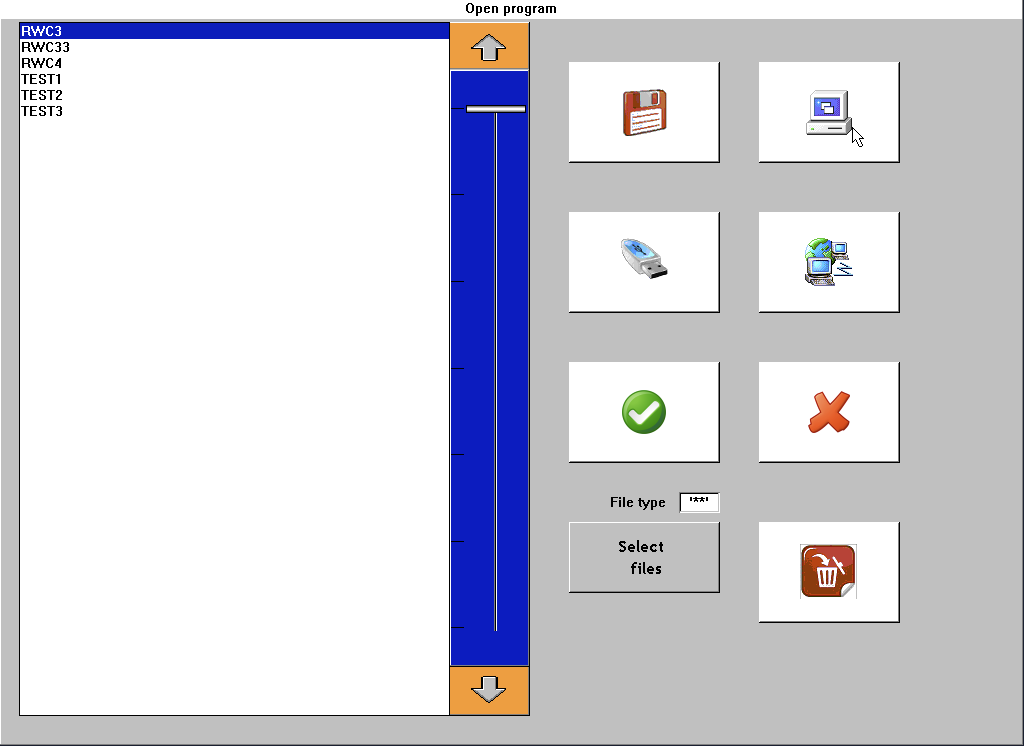

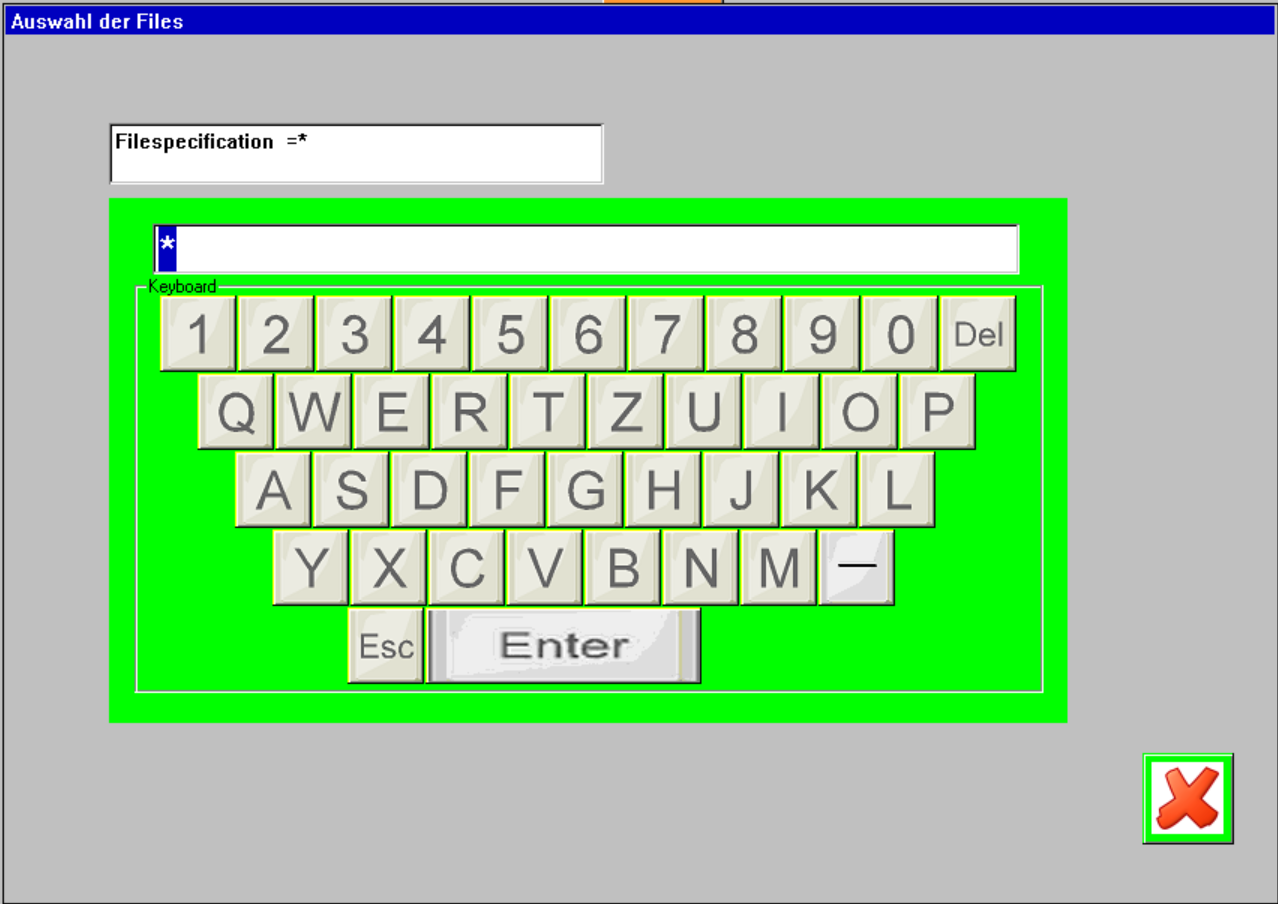

Neben den grundlegenden Funktionen wie Öffnen, Speichern, Kopieren, Löschen, Bearbeiten und Drucken von Wickelprogrammen bietet die Software zahlreiche zusätzliche Funktionen:

- Integrierte Sprachumschaltung für den internationalen Einsatz

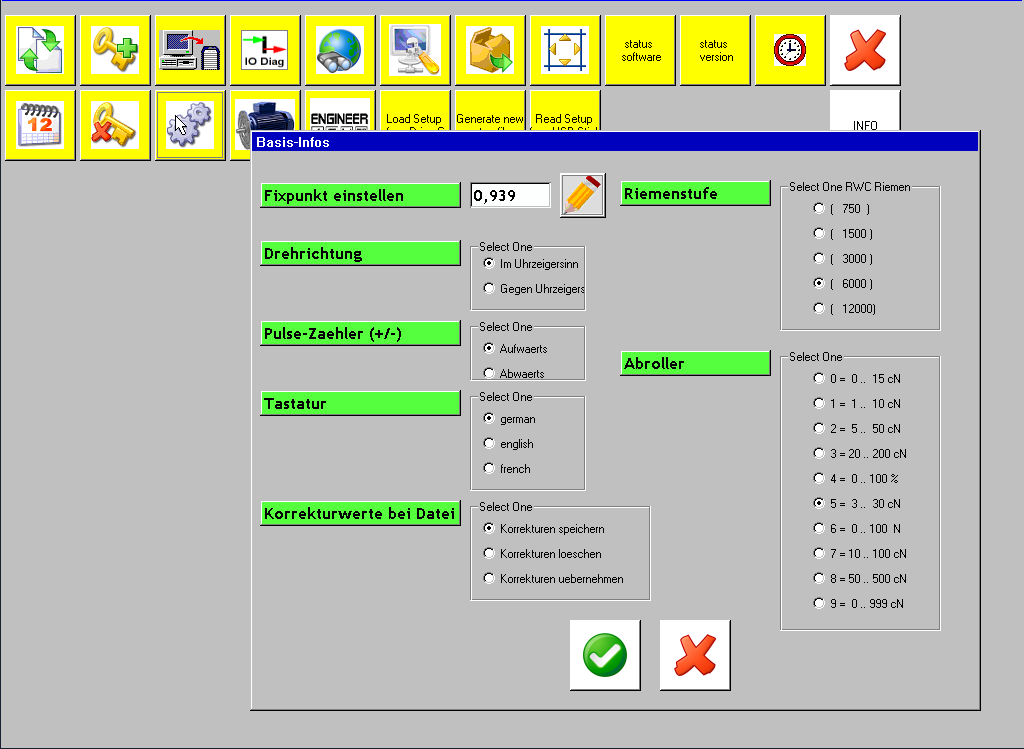

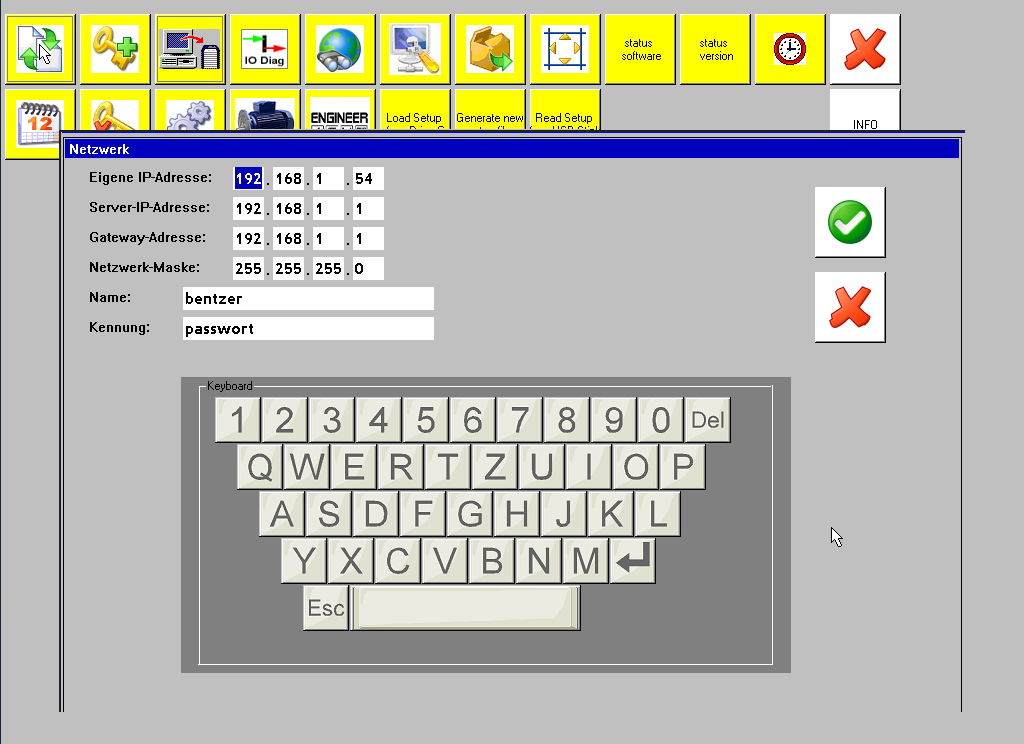

- Umfangreiche Konfigurationsmöglichkeiten

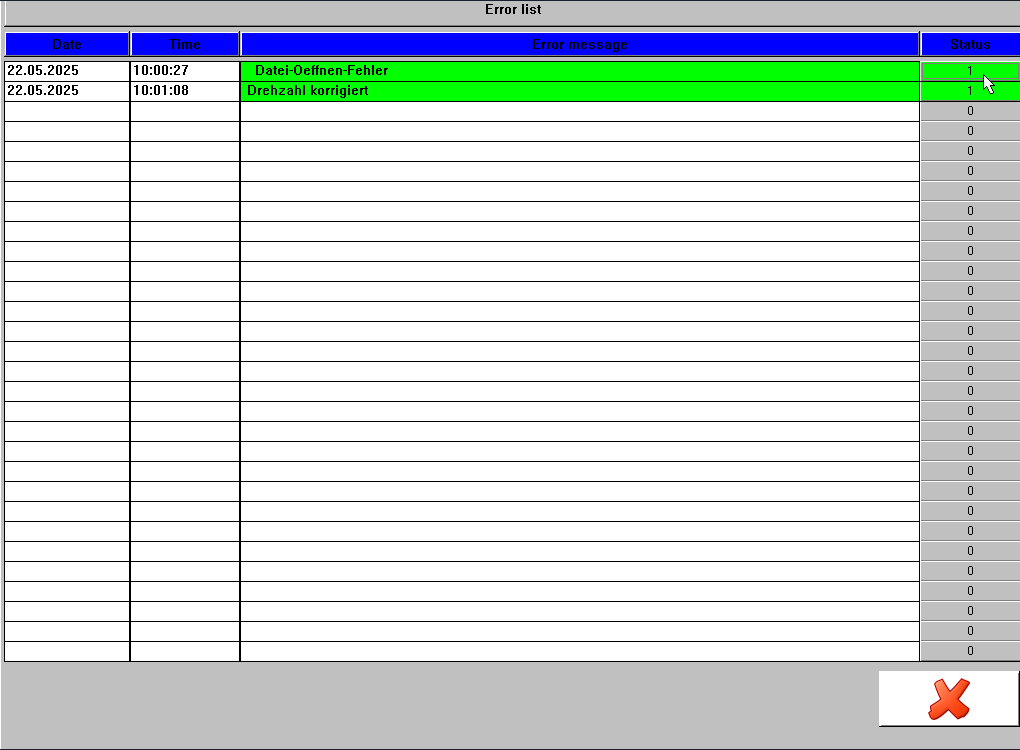

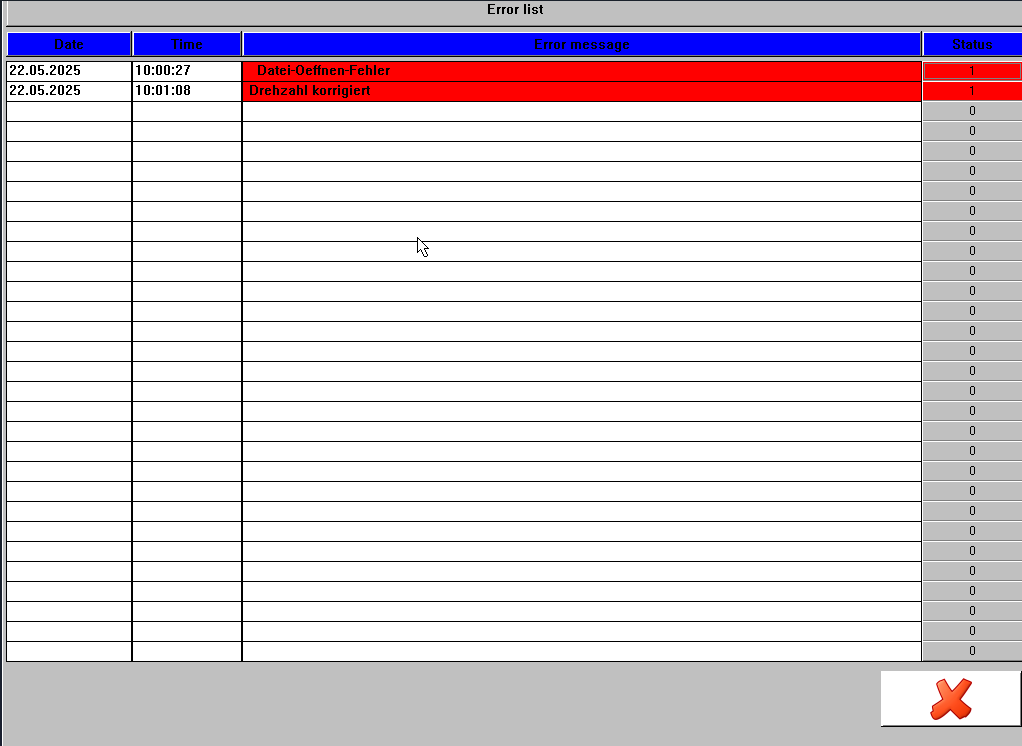

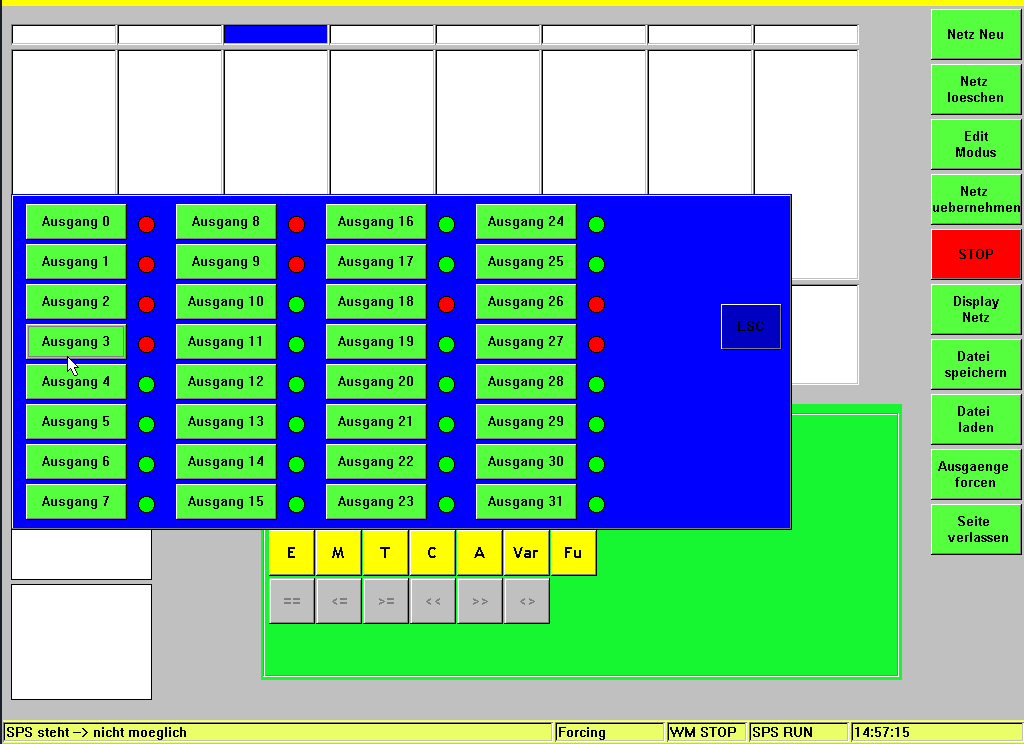

- Servicerelevante Diagnosetools

- Funktionen zur Systemoptimierung & Maschinenanpassung

Dank der klar strukturierten Oberfläche unterstützt die Software sowohl Maschinenbediener im Produktionsalltag als auch Fachpersonal bei der Konfiguration und Anpassung der Wickeltechnik.